Features

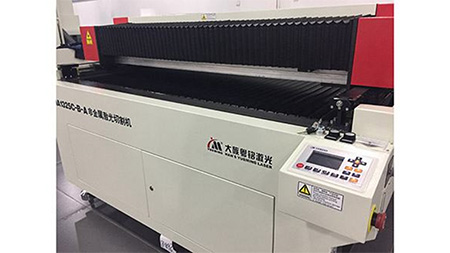

- Machine body is made of reinforced welding frame, 600℃ heat treatment and vibration aging to do stress release and then under finishing milling to get high stability and to keep the deformation tolerance within ± 0.02mm.

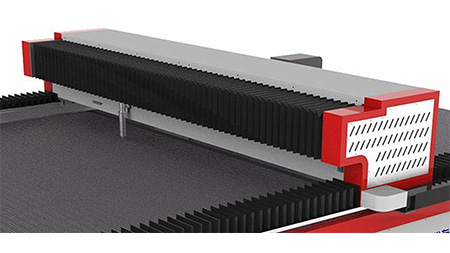

- High strength aluminum alloy is adopted for the beam structure to ensure faster and smoother running.

- High dynamic step motor and high precision linear guide rail are adopted to achieve fast response and stable performance.

- Support MDF, acrylics and the other materials cutting.

Technical Parameter

| Maximum material size | 1325mm×2500mm |

| Laser power | 80W~150W |

| Maximum speed | 25m/min |

| Positioning Accuracy | ±0.1mm |

| Repeated accuracy | ±0.05mm |

| Cooling method | Water cooling |

| Drawing format | BMP,PLT,DST,AI,ETC |

| Work environment | Temperature 5-40℃ Humility≤ 95%, No condensation |

| Gross power | <4KW |

| Supply voltage | 220V/50Hz-60Hz |

| Machine weight | 600Kg |

| Dimension | 3480*1900*1150 mm |

Parts Introduction

Rubbish trolley ensure easy cleaning for all the wastage.

Rubbish trolley ensure easy cleaning for all the wastage.

Small and smart operating controller,occupies few space.

Small and smart operating controller,occupies few space.

Laser tube move together with cutting head, to ensure the consistency cutting effect for the whole working area.

Laser tube move together with cutting head, to ensure the consistency cutting effect for the whole working area.

Welded steel frame after effective heat treatment and annealing treatment, it enjoys good rigidity, long-term stability and no deformation.

Welded steel frame after effective heat treatment and annealing treatment, it enjoys good rigidity, long-term stability and no deformation.

Imported servo motor is in accordance with 3C and CE certification, which can work stably in long time without losing step or burnout.

Imported servo motor is in accordance with 3C and CE certification, which can work stably in long time without losing step or burnout.

Siemens/Schneider electrical components;comply with CE standards; enjoy strong anti-jamming ability.

Siemens/Schneider electrical components;comply with CE standards; enjoy strong anti-jamming ability.

Application

Material

Non-metal materials such as acrylics, wood, MDF.

Sample:

emitting word laser cutting

emitting word laser cutting

Board laser cutting

Board laser cutting

Crystal acrylic 3D wall stickers laser cutting

Crystal acrylic 3D wall stickers laser cutting

Crystal words laser cutting

Crystal words laser cutting

Plywood laser cutting

Plywood laser cutting

PMMA board laser cutting

PMMA board laser cutting

Rubber plate laser cutting

Rubber plate laser cutting

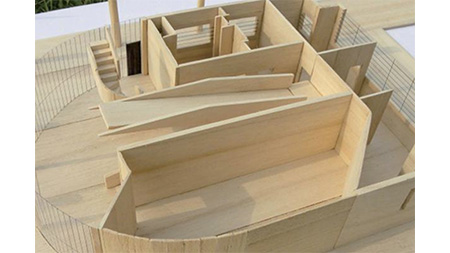

Wood laser cutting machine-Craft gift model laser cutting

Wood laser cutting machine-Craft gift model laser cutting