Features

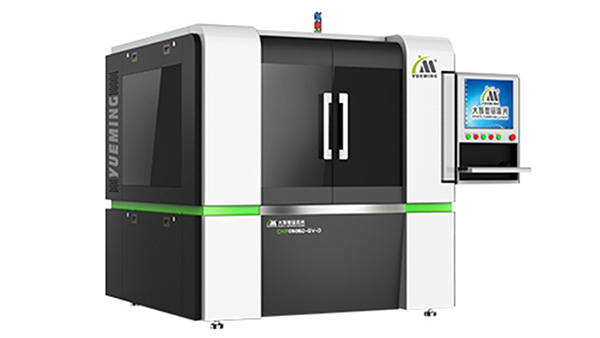

- The machine, with overall casting structure, high accuracy and stability, effectively eliminate the vibration generated during high-speed cutting;

- Dual lead screws, dual-motor drive system, high-speed arc cutting function;

- Automatic lubrication system, maintenance-free transmission components, and the ability to cut corrosive materials;

- Possessing the power, frequency and speed following function effectively reduces yellowing result of corners cutting.

Technical Parameter

| Model | CMA0606D-G-B / CMA0606D-GV-B (with Camera shooting CCD) |

| Working area | 600mm×600mm |

| Laser power(optional) | 500W~1000W (optional) |

| Lubrication system | Full-automatic |

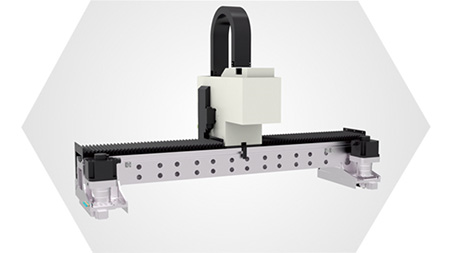

| Drive system | Gantry double lead screws servo drive |

| Machine structure | Overall casting |

| Maximum working speed | 60m/min |

| Maximum acceleration | 1.2 G |

| Positioning accuracy | ±0.02mm |

| Reposited positioning accuracy | ±0.01mm |

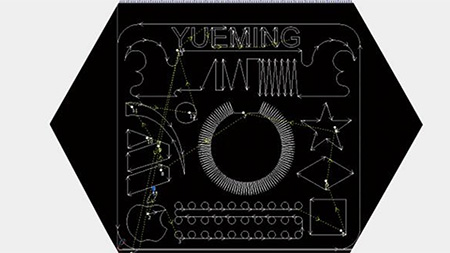

| Graphic format supported | PLT、DXF、AI、CAD etc. |

| Working environment | 0-40℃ humidity≤ 80%,non-condensation |

| Total power | 5KW |

| Power supply | Triphase 380V/50Hz/60Hz |

| Overall dimension | 2000mm×1680mm×2000mm |

| Total weight | 2400Kg |

Parts Introduction

Imported fiber laser

Imported fiber laser

Y axis synchronized dual-motor

Y axis synchronized dual-motor

Focusing system (optional)

Focusing system (optional)

Precise moving component

Precise moving component

Cooling system

Cooling system

Professional steel plate cutting software

Professional steel plate cutting software

YASKAWA servo motor

YASKAWA servo motor

Gantry structure

Gantry structure

Application

Material:

Mainly used for high-speed cutting carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, Galvanize sheet, brass, copper etc.

Sample:

Aluminum fiber precision laser cutting

Aluminum fiber precision laser cutting

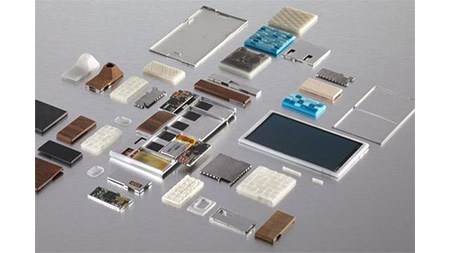

Electrical parts fiber precision laser cutting

Electrical parts fiber precision laser cutting

fiber precision laser cutting components of phone

fiber precision laser cutting components of phone

fiber precision laser cutting metal case

fiber precision laser cutting metal case

fiber precision laser cutting metal chips

fiber precision laser cutting metal chips

fiber precision laser cutting metal spectacle frames

fiber precision laser cutting metal spectacle frames

Metal U disk fiber precision laser cutting

Metal U disk fiber precision laser cutting

Precision Auto Parts fiber precision laser cutting

Precision Auto Parts fiber precision laser cutting