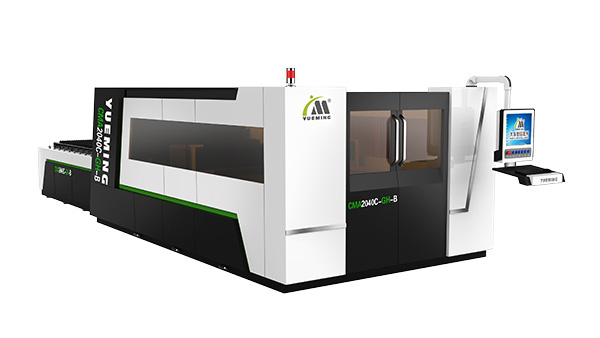

Features

- High-rigidity heavy chassis, reducing the vibration generated during high-speed cutting greatly.

- Gantry double-drive structure, with imported German rack & pinion transmission system, improves the production efficiency.

- High-performance cast aluminum guide rail, after finite element analysis, realizes highly accelerated speed circular arc cutting.

- Close-loop laser cutting control system, auto focus, high-speed piercing and automatic tracing-edge function.

Technical Parameter

| Working area | 2000mm×4000mm |

| Laser type | Fiber laser generator |

| Laser power(optional) | 1000W~4000W |

| Transmission system | Gantry double-drive system |

| Lubrication system | Full-automatic |

| Maximum speed | 120m/min |

| Maximum accelerated speed | 1.2 G |

| Position accuracy | ±0.03mm/1000mm |

| Reposition accuracy | ±0.02mm/1000mm |

| Compatible formats | PLT、DXF、AI、CAD etc |

| Total power | Around 25KW |

| Power supply | Triphase 380V/50Hz/60Hz |

| Net dimension | 10600mm×3470mm×1875mm |

| Gross weight | 12000Kg |

| Working environment | Temp:0-40℃,humidity: ≤ 80%, No condensation |

Parts Introduction

Imported fiber laser

Imported fiber laser

Y axis synchronized dual-motor

Y axis synchronized dual-motor

Focusing system (optional)

Focusing system (optional)

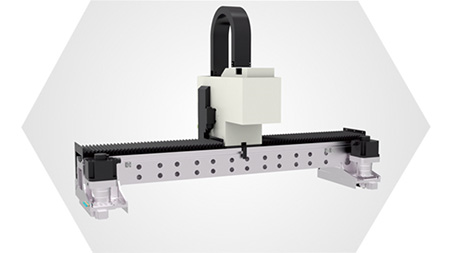

Precise moving component

Precise moving component

Cooling system

Cooling system

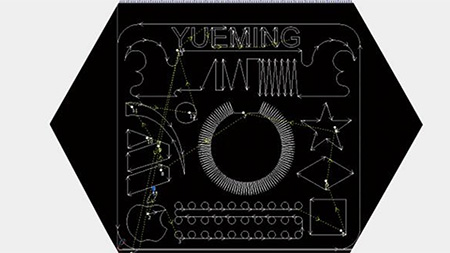

Professional steel plate cutting software

Professional steel plate cutting software

YASKAWA servo motor

YASKAWA servo motor

Gantry structure

Gantry structure

Application

Material

Metal materials such as Carbon steel, Stainless steel, Aluminum alloy, Titanium alloy, Galvanize sheet, Brass, Red copper etc.

Sample

Kitchenware laser cutting

Kitchenware laser cutting

Kitchenware stainless steel cooking stove laser cutting

Kitchenware stainless steel cooking stove laser cutting

Laser cutting of cabinet and sheet metal

Laser cutting of cabinet and sheet metal

Laser cutting of cabinet,stainless steel and sheet metal

Laser cutting of cabinet,stainless steel and sheet metal

Laser cutting of central air conditioning and sheet metal

Laser cutting of central air conditioning and sheet metal

Laser cutting of central air conditioning

Laser cutting of central air conditioning

Laser cutting of central air

Laser cutting of central air

Laser cutting of central air conditioning conditioning and sheet metal

Laser cutting of central air conditioning conditioning and sheet metal