Features

- Equipped with PRECITEC new generation pro-cutter laser cutting head, Optimized cutting process, monitoring cutting conditions through“APP”use easily and friendly;

- High rigidity welded body has been treated with Vibrate Stress Relief and heat treatment to improve the body strength and little deformation;

- High precision servo motor and transmission system, this system enjoys high precision, big transmission torque, tiny transmission errors and good dynamics;

- With ergonomic design, equipped with intelligent operation terminal, user-friendly and easy to learn.

- Eagle eye (CCD) technology, ultra-fast positioning the sheet metal edge, minimum cutting down time. In addition, it also can process punching parts and precut parts, due to secondary positioning function.

- Optimized cutting technology with Programmable laser frequency and focus position, to achieve high efficiency processing on different thickness & type sheet metal. All cutting parameters can be programmed, no need human intervention, use easily and friendly;

- Automatic energy saving mode: while stop over 5 minutes, machine automatically switch into "standby" mode, to reduce power consumption;

- Auto exchanging table with Hydraulic lifting system; ensure synchronous running , reliable and stable;

- Programmable Cutting gas thanks to Ser vo-control valve, it can switch the type of cutting gas automatically, and accurate control the gas pressure without user intervention,use friendly and reduce gas consumption.

Technical Parameter

| Working area | Wind3015: 3000x1500mm Wind4020: 4000x2000mm Wind6025: 6000x2500mm |

| Output laser power | 3000W/4000W/6000W |

| WTransmission system | synchronous driving system with high torque servo motor |

| Loading method | Automatic exchanging pallets |

| Max speed | 169m/min |

| Accelerated speed | 1.5g |

| Position accuracy | ±0.05mm(VDI/DGQ3441) |

| Reposition accuracy | ±0.03mm(VDI/DGQ3441) |

| Total power | 11Kw/13Kw/19Kw |

| Gross weight | 10T/13.5T/15.5T |

| Overall dimension | Wind3015: 9800x3000x2200mm Wind4020: 12000x3500x2200mm Wind6025: 15500x4200x2200mm |

Parts Introduction

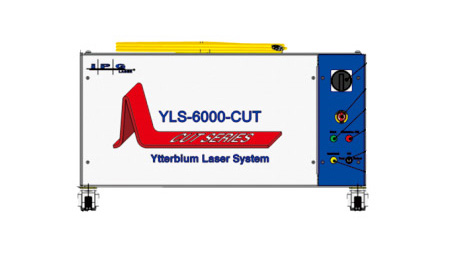

Adopts the new IPG fiber laser source, enjoys better laser beam quality, stablepower, less electricity consumption and longer working life.

Adopts the new IPG fiber laser source, enjoys better laser beam quality, stablepower, less electricity consumption and longer working life.

Machine equipped with Bechhoff CNC system, with EtherCAT real-time control protocol, reduce machine downtime and ensure fast response. Besides, the extended automation system and applications can be easily integrated into machine thanks to the open automation systems of Beckhoff CNC.

Machine equipped with Bechhoff CNC system, with EtherCAT real-time control protocol, reduce machine downtime and ensure fast response. Besides, the extended automation system and applications can be easily integrated into machine thanks to the open automation systems of Beckhoff CNC.

Special molding technique made aviation aluminum gantry, light weight, strong rigidity, equips with integrated Z-axis system, to enjoy high precision, fast response and stable running.

Special molding technique made aviation aluminum gantry, light weight, strong rigidity, equips with integrated Z-axis system, to enjoy high precision, fast response and stable running.

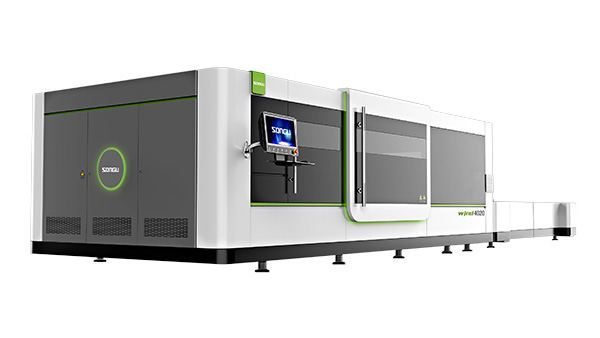

Fully enclosed housing, Safety circuit design, equipped with laser radiation-shielding glass, Higher safety standard, Ensure the safety of operators

Fully enclosed housing, Safety circuit design, equipped with laser radiation-shielding glass, Higher safety standard, Ensure the safety of operators

Programmable Cutting gas thanks to Servo-control valve, it can switch the type of cutting gas automatically, and accurate control the gas pressure without user intervention,use friendly and reduce gas consumption

Programmable Cutting gas thanks to Servo-control valve, it can switch the type of cutting gas automatically, and accurate control the gas pressure without user intervention,use friendly and reduce gas consumption

Application

Material

Metal materials such as carbon steel, stainles steel, aluminum alloy, titanium alloy, galvanize sheet, brass, red copper etc.

Sample:

-