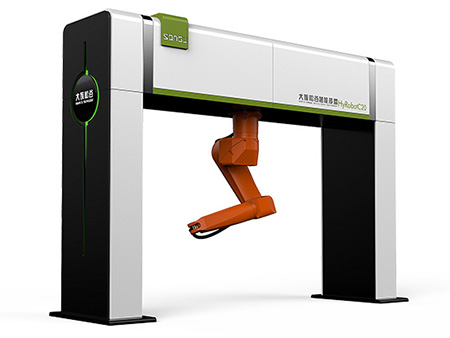

Features

- High precision Staubli industrial robot, aluminum alloy arm, light weight; The unique hoisting device ensures the operating accuracy under any posture.

- Using fiber laser source, the beam has good quality, stable power and low energy consumption. Fiber transmission, small energy loss, protective safety, convenient installation.

- The robot is equipped with gantry crane, which has a large working range and is close to the loading area. It can process large sheet metal forming parts.

- Equipped with the laser cutting head with the leapfrog function, the structure is compact, the weight is light, the focus lens is double protected, and the cost is low.

- The fully enclosed outer protective device adopts the safety interlock design, effectively isolating the processing zone, avoiding the radiation damage of the laser and high safety.

- Intelligent operation terminal, simple interface, clear identification, easy to learn; Embedded process database, flexible use, effectively reduce the use of difficulty.

- Robot fiber cutting system with remote diagnosis, remote assistance function, after-sales service response fast.

- The robot and the cutting head are equipped with reliable collision quick reset device to effectively protect the key parts.

- It can organize a certain number of cutting units to form an automated production line to meet the production needs of medium batch.

Technical Parameter

| Mechanical arm span | 2010mm |

| Output laser power | 1000W |

| Working abutment | 2000×2000mm (Fixed type) |

| Axis1 | ±160º |

| Axis2 | ±147.5º / -130º |

| Axis3 | ±145º |

| Axis4 | ±270º |

| Axis5 | ±140º / -115º |

| Axis6 | ±360º |

| Reposition accuracy | ±0.05mm (VDI/DGQ3441) |

| Total power | 11Kw |

| Gross weight | 3T |

| Overall dimension | 7000×4000×3200 mm |

Parts Introduction

-

Application

Main application:

In the process of product modification, after stamping sheet metal parts laser cutting process and edge removal are used to replace blanking die and cutting edge die stamping.

After the high strength steel plate hot forming, secondary cutting process.