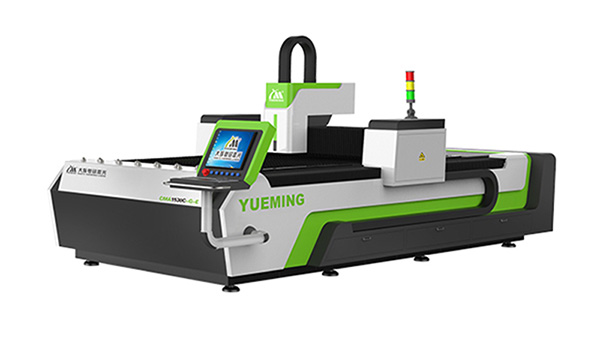

Features

- Gantry rack double drive system, reinforced welding body. The stress is eliminated by tempering and vibration aging to ensure that the machine deformation tolerance is within 0.02 mm;

- High performance German imported laser generator: Continuous cutting high reflecting material, such as copper, brass, galvanized sheet, to achieve high precision cutting of metal sheets;

- Crossbeam are made through drawing and finishing process: Light weight, high rigidity, high dynamic performance;

- Cutting head has the leapfrog function, parabolic mo on between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

- Automatic concentrated lubrication function, automatic lubrication for traditional parts by system control. No manual intervention is needed so as to ensure the accuracy and service life of the moving part;

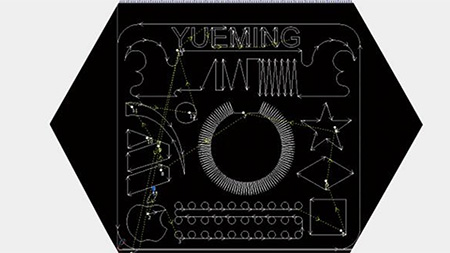

- Professional metal sheet cutting so ware, support AI, DXF, PLT graph data format, easy to learn and use and reduce the requirements of the operator.

Technical Parameter

| Model | CMA2040C-G-A | CMA1540C-G-A | CMA1530C-G-E |

| Laser power (W) | 700-2000 | 500-1500 | |

| Working area (mm) | 2000*4000 | 1500*4000 | 3000*1500 |

| Overall dimension (mm) | 6400*2700*2000 | 6400*2200*2000 | 5400*2200*2000 |

| Weight (kg) | 4800 | 4500 | 4000 |

| Positioning accuracy (mm) | ±0.03/1000 | ||

| Repeated positioning accuracy (mm) | ±0.02/1000 | ||

| Maximum speed (m/mim) | 60 | ||

| Maximum accelerated speed (m/min) | 0.8 | ||

| Supply voltage | Three phase 380V/50Hz/60Hz | ||

| Working environment | Temp: 0-45℃, Humidity:≤80% | ||

Parts Introduction

Gantry structure

Gantry structure

YASKAWA servo motor

YASKAWA servo motor

Professional steel plate cutting software

Professional steel plate cutting software

Cooling system

Cooling system

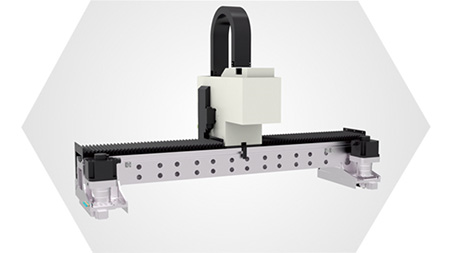

Precise moving component

Precise moving component

Focusing system (optional)

Focusing system (optional)

Y axis synchronized dual-motor

Y axis synchronized dual-motor

Imported fiber laser

Imported fiber laser

Application

Material

Metal materials such as Carbon steel, Stainless steel, Aluminum alloy, Titanium alloy, Galvanize sheet, Brass, Red copper etc.

Sample:

Electrical contact element cutting

Electrical contact element cutting

Hotelmetalsupplies cutting

Hotelmetalsupplies cutting

Lighting metal back cutting

Lighting metal back cutting