Features

Laser Process Advantages

The laser JQ1530C optimizes your manufacturing process in several ways. In a single operation you can create perforations and complex contours. In addition, tubes can be cut into sections. This enables innovative design solutions that minimize downstream tasks such as deburring, welding, and assembly. The resources required for intermediate stages such as storage and part handing are also much lower, as a result you can steep up your process and significantly reduce costs per part over production methods that use conventional tools for sawing, drilling and milling.

LED TOUCH SCGREEN

But also greatly reduces the single-sided cutting when the unnecessary lift, save time.

Technical Parameter

| Name | Parameter | Unit |

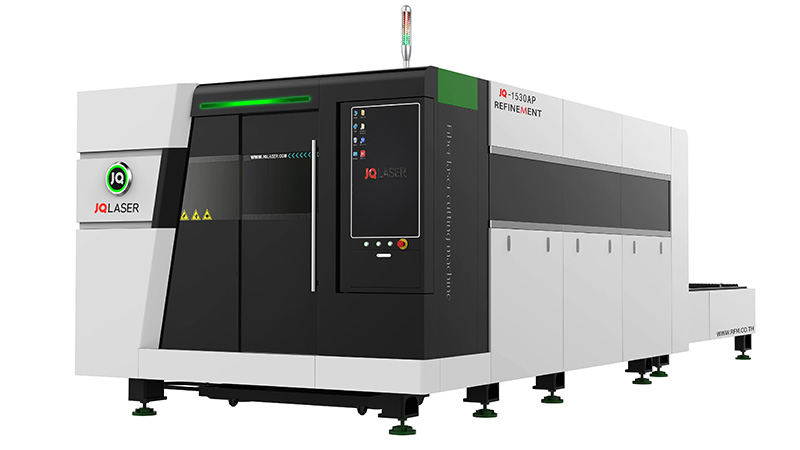

| Machine model | JQ1530AP | |

| Laser Source | Raycus | 1000-3000w |

| Water cooler Power | 10 | kw |

| CNC | Fscut2000 | |

| Guide | HIWIN | |

| Gear | YYC | |

| Motor | Yaskawa | |

| Reducer | Beitto | |

| Pneumatic parts | Airtech | |

| Electric parts | CHINT | |

| Minimum cutting width | 0.08-0.15 | mm |

| Maximum cutting thickness | 8-20 | mm |

| Maximum moving speed | 100 | m/min |

| Working area | 1500*3000mm | mm |

| Electricity requirements | 380/50,60 | v/hz |

| Graphic Format Supported | AutoCAD, | |

| Acceleration | 1.5 | G |

| Total power | 31 | kw |

| Presser of N2/O2/AIR | 15-20/6-8/15-30 | bar |

| Load | 500 | kg/cbm |

| Total Weight | 7 | t |

| Work per day | 24 | h |

| Lay out | 7615*2506*2018 | mm |

| Oil Box | Auto Oil Injection System |

Application

Function

Supports three levels of perforation

Support flying cutting, frog jumping, compensation, lead wire, micro connection, pre-perforation, film cutting and other processes

Supports capacitor edge search, electric focus adjustment, power-off memory and other functions

Supports cooling points, sharp corners