Features

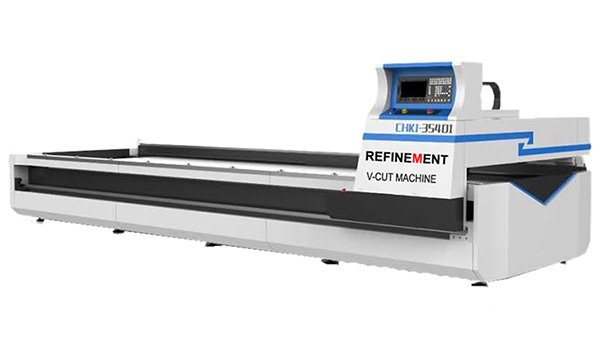

This machine is made up of base, cross bar, rest, CNC system, pneumatic system, compress blow, cooler system. It is in the gantry movable structure

- Box-type base and cross bar, optimal design, all welded and tempering, high strength and high precision.

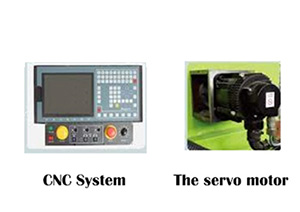

- CNC system control the rest move forward and backward(Y1 axis), up and down(Z axis), side holder move forward and backward (Y2 axis), AD servo motor drive, ball screw drive transmit, high precision and accurate positioning AC frequency adjustable-speed motor drive cross bar move left and right(X axis), helical pinion and rack transmission, high load.

- Pneumatic clamping system, clamp the work pieces with different thickness to prove the process precision.

- Compressed air blow and cooler system to protect the work piece surface, improve the life of the knife by cooling the knife.

Specification

| Model | Max. grooving width | Max. grooving length | Max. grooving thickness | Min. grooving thickness | Min. grooving distance | M/Min (max) | Knife rest resolution (left and right) | Positioning accuracy | Knife rest resolution | Positioning accuracy | Main motor power | Hydraulic system | Dimensions | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kw | Mpa | Length | Width | Height | ||

| 1220x2500 | 1220 | 2500 | 4.5 | 0.6 | 8 | 65 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 4500 | 2320 | 1600 |

| 1220x3200 | 1220 | 3200 | 4.5 | 0.6 | 8 | 65 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 5200 | 2320 | 1600 |

| 1220x4000 | 1220 | 4000 | 4.5 | 0.6 | 8 | 65 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 6000 | 2320 | 1600 |

| 1500x4000 | 1500 | 4000 | 4.5 | 0.6 | 8 | 45 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 6000 | 2480 | 1600 |

| 1220x5000 | 1220 | 5000 | 4.5 | 0.6 | 8 | 65 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 7000 | 2300 | 1600 |

| 1220x6000 | 1220 | 6000 | 4.5 | 0.6 | 8 | 65 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 8000 | 2300 | 1600 |

| 1500x6000 | 1500 | 6000 | 4.5 | 0.6 | 8 | 45 | 0.001 | ±0.01 | 0.001 | ±0.01 | 5.5 | 6–8 | 8000 | 2480 | 1600 |