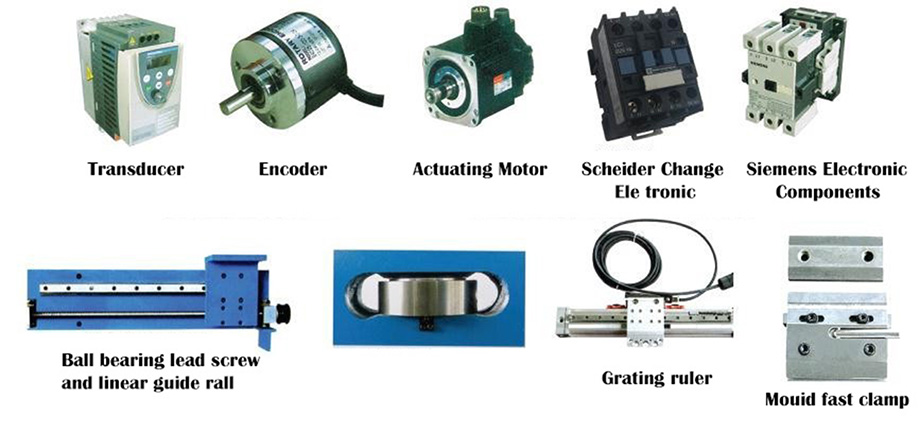

The model of hydraulic plate bending machine as the simple CNC controller,it can control the movement of backgauge,achieving efficient and highly precise positioning;Integrated hydraulic system with hydraulic elements and sealing parts from reputable manufacturers to reduce hydraulic tubes and ensure highly reliable and sage performance.

Basic features

- Total steel welded structure and stress elimination by vibration.

- High mechanical strength and strong rigidity.

- Ram stroke hydraulic approaching downward,stable and reliable.

- E21 can control the movement of ram stroke and backgauge,achieving efficient and highly precise positioning.

- Wedge compensation on top punch clamping.

- Simplified top blades clamping with micro-adjustment wedges,for easy operation and high precision.

- 2 Sliding front sheet support arms mounted onto T slot of the bed.

- Segmented 88° top blade.

- Solid one block four face multi V die.

- Approved stable and reliable hydraulics.

- Stop fingers with milscale for plate bending machine.

WC67Y/K series hydraulic press brake machine technical parameters

| Model | Nominal Pressure (mm) |

Length of working table (mm) | Distance benweet uprights ( ° ) | Throat depth (mm) |

Ram stroke (mm) |

Main Motor Power (kw) |

| WC67Y/K-40/2500 | 400 | 2500 | 2000 | 200 | 100 | 4 |

| WC67Y/K-63/2500 | 630 | 2500 | 2000 | 250 | 120 | 5.5 |

| WC67Y/K-63/3200 | 630 | 3200 | 2490 | 250 | 120 | 5.5 |

| WC67Y/K-80/3200 | 800 | 3200 | 2490 | 250 | 120 | 5.5 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2490 | 320 | 120 | 7.5 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3000 | 320 | 120 | 7.5 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2490 | 320 | 120 | 7.5 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3000 | 320 | 120 | 7.5 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2490 | 320 | 180 | 11 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3000 | 320 | 180 | 11 |

| WC67Y/K-160/6000 | 1600 | 6000 | 4100 | 320 | 200 | 11 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2490 | 320 | 200 | 11 |

| WC67Y/K-200/4000 | 2000 | 4000 | 3000 | 320 | 200 | 11 |

| WC67Y/K-200/6000 | 2000 | 6000 | 4600 | 320 | 200 | 15 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2500 | 350 | 250 | 15 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3000 | 350 | 250 | 15 |

| WC67Y/K-250/6000 | 2500 | 6000 | 4600 | 350 | 200 | 15 |

| WC67Y/K-300/3200 | 3000 | 3200 | 2600 | 350 | 250 | 18.5 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3000 | 350 | 250 | 18.5 |

| WC67Y/K-300/6000 | 3000 | 6000 | 4600 | 350 | 250 | 18.5 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3100 | 350 | 250 | 22 |

| WC67Y/K-400/5000 | 4000 | 5000 | 3600 | 350 | 250 | 22 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4600 | 350 | 250 | 30 |

| WC67Y/K-500/4000 | 5000 | 4000 | 3100 | 350 | 250 | 30 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4600 | 350 | 250 | 30 |

| WC67Y/K-500/8000 | 5000 | 8000 | 6100 | 350 | 250 | 30 |

| WC67Y/K-600/6000 | 6000 | 6000 | 4600 | 400 | 300 | 37 |

| WC67Y/K-600/8000 | 6000 | 8000 | 6100 | 400 | 300 | 45 |

| WC67Y/K-800/6000 | 6000 | 6000 | 4600 | 400 | 300 | 45 |

| WC67Y/K-800/8000 | 8000 | 8000 | 6100 | 400 | 300 | 55 |

| WC67Y/K-1000/6000 | 10000 | 6000 | 4600 | 500 | 400 | 55 |

| WC67Y/K-1000/8000 | 10000 | 8000 | 6100 | 400 | 400 | 55 |

| WC67Y/K-1200/6000 | 12000 | 6000 | 4600 | 600 | 400 | 75 |

| WC67Y/K-1200/8000 | 12000 | 8000 | 6100 | 600 | 400 | 75 |

| WC67Y/K-1600/8000 | 16000 | 8000 | 6100 | 600 | 400 | 2 x 55 |

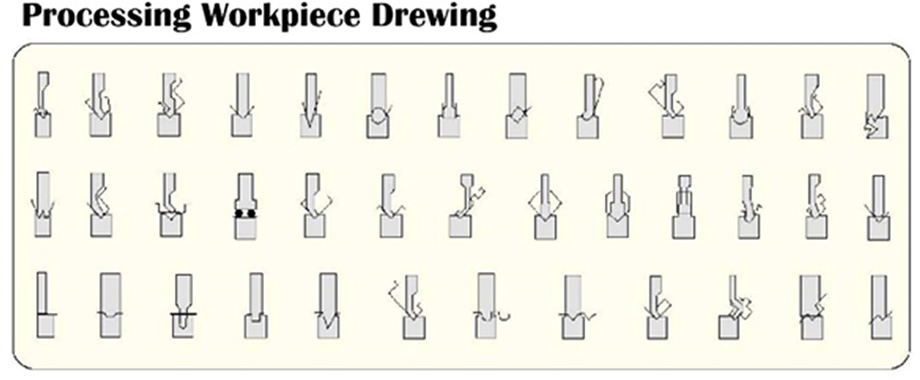

Application