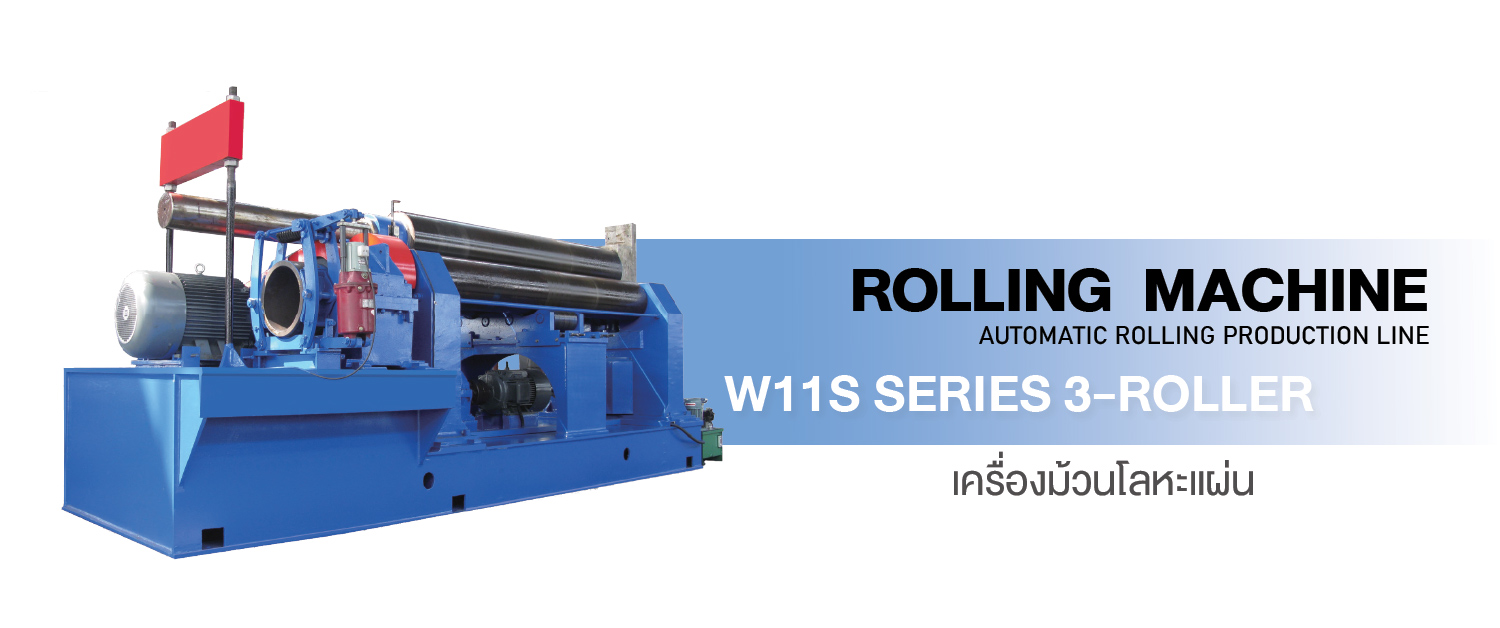

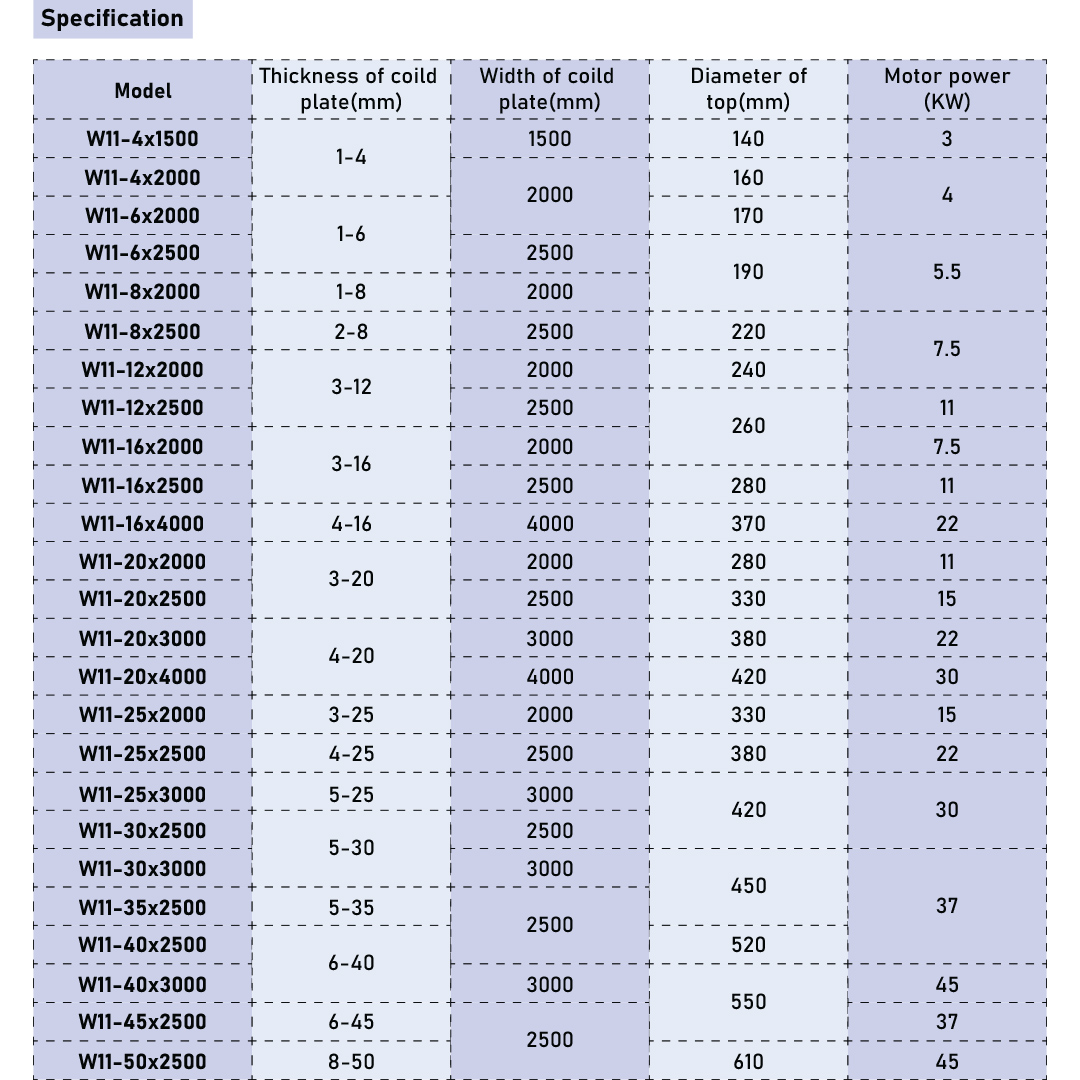

W11S Series 3-roller

เครื่องม้วนโลหะแผ่น คาร์บอนสตีล สแตนเลส อลูมิเนียม

Total: 120 results found.

Page 2 of 6

Features - High precision end pre-bending: The straight edge length can be set freely, while the upper roller press to pre-bend. - NC control, high productivity. - Good accuracy: Upper roller like drum, lower rollers assorted with it through support roller. Able to bend continuously and roll ideal products from thin to thick plate widely. - Safety: Fixed lower rollers with moveable upper roller. Jobs do not move with the working rollers. - Complete structure, simple foundation, convenient move: Machine has unitary basement, which does not require earth bolts. - Plenty of bending shapes: Able to roll shapes of O (backside roll way), U (front side roll way), several R (combined way), taper in certain range.

| Model | FST-SC-3000W |

Laser Power |

3000W |

Power Source |

Max |

Working speed: |

0-7200mm/min |

function |

Welding cleaning and cutting |

operating system |

QILIN |

cleaning mode |

Lines, circles, snowflakes, bull heads, hot wheels. |

Welding mode |

point, line, circle, ellipse, triangle, figure 8, semicircle |

Laser wave length: |

1070nm |

Range of adjustable power |

1-100% |

Repeat frequency: |

5-10KHz (adjustable) |

Pulse width: |

Continuous light |

Welding depth: |

≤1.2mm |

Power supply: |

AC220V/AC110V±10%,50HZ/60HZ |

Repeat Precision: |

±0.01mm |

Power stability: |

±2% |

Service medium: |

Rare earth doped fiber |

Length of fiber-optional: |

10m (standard) |

Beam Quality: |

Single mode / Multi mode. |

Module life: |

>100000 hrs |

Cooling style: |

Water cooling |

Interface of fiber-optical: |

QBH |

Welding materials: Stainless steel, Galvanized plate, Iron sheet, Brass, Aluminum etc. |

|

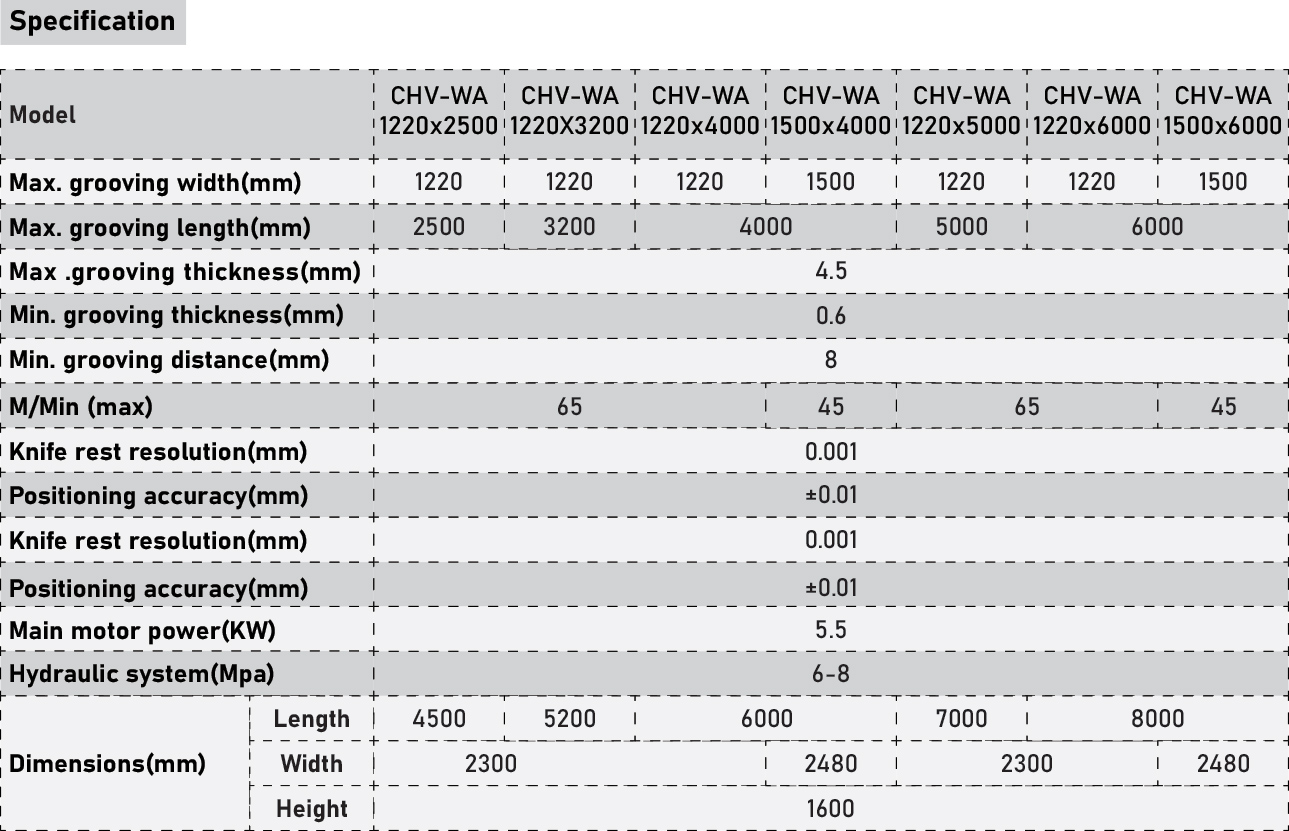

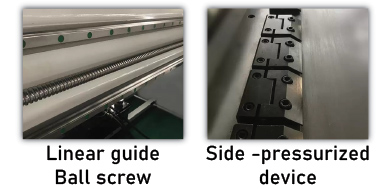

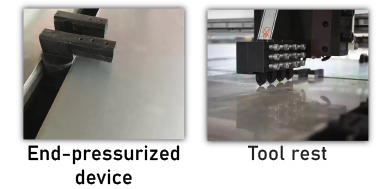

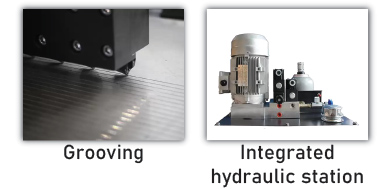

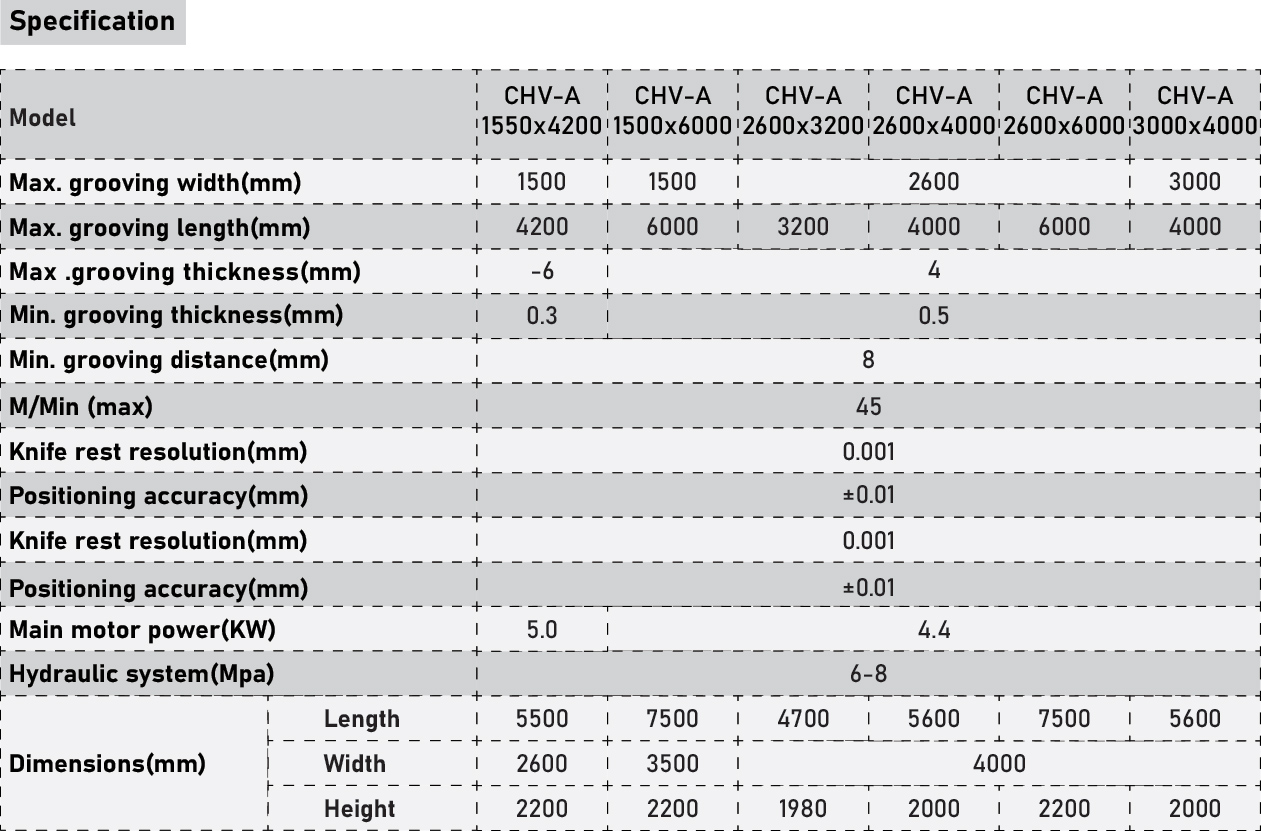

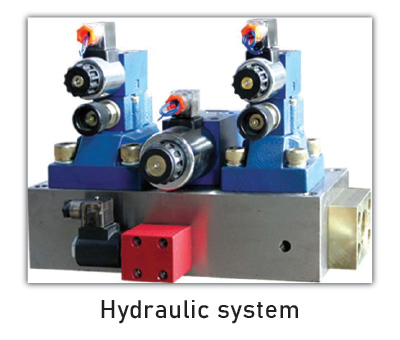

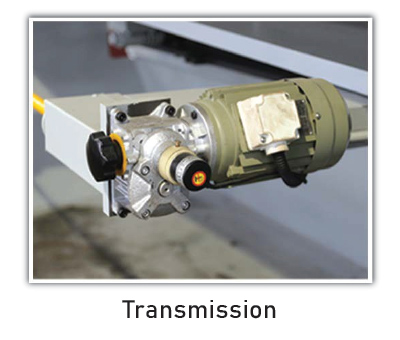

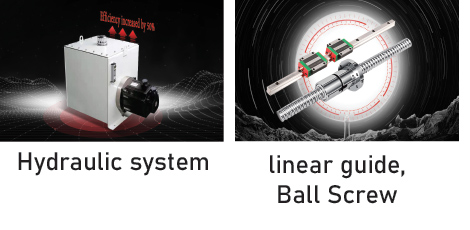

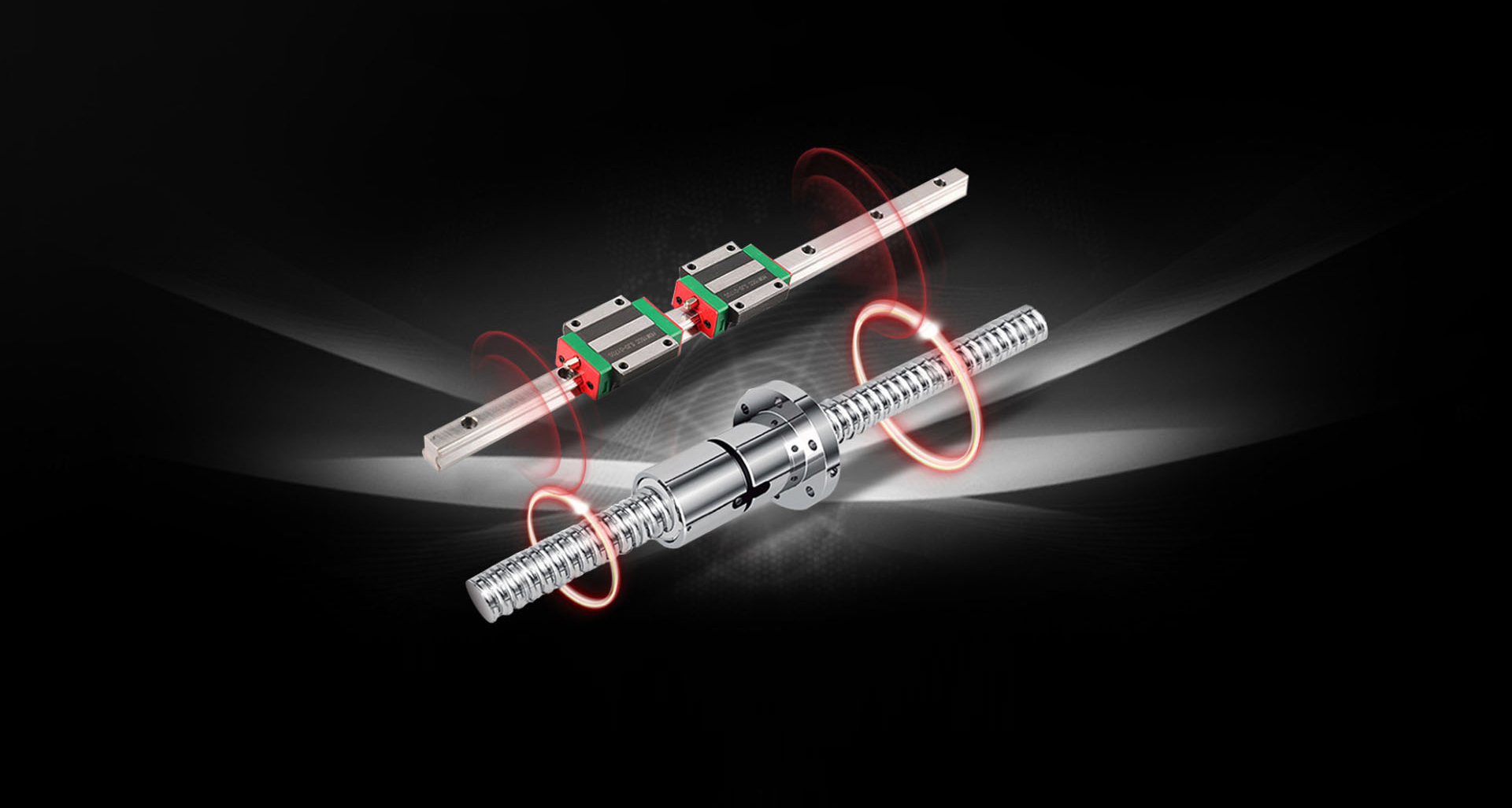

Features - Adopt all steel welded structure,the residual stress is eliminated by tempering furnace, and the machine is with high mechanical strength and good rigidity. - Adopt hydraulic pressurized system,which largely improves the processing accuracy. - X axis is driven by AC motor.Y1 axis / Y2 axis / Z axis are driven by servo motor. Higher performance higher, efficiency,save energy Internet. - Integrated hydraulic station imported brand hydraulic valve parts compact structure and low failure rate. - Manually lubrication system reduces mechanical friction. - Foot pedal with emergency stop. - High efficiency chip blowing device to avoid workpiece damaged. - Less power consumption. - Low noise & smooth operation gives higher efficiency of operator. - Water cooling system cooling blades reduced wear increase using life. - The moving system adopts ball screw and linear guide. - The grooving structure of four blades improve the working efficiency. - Electric components are all with famous brand.

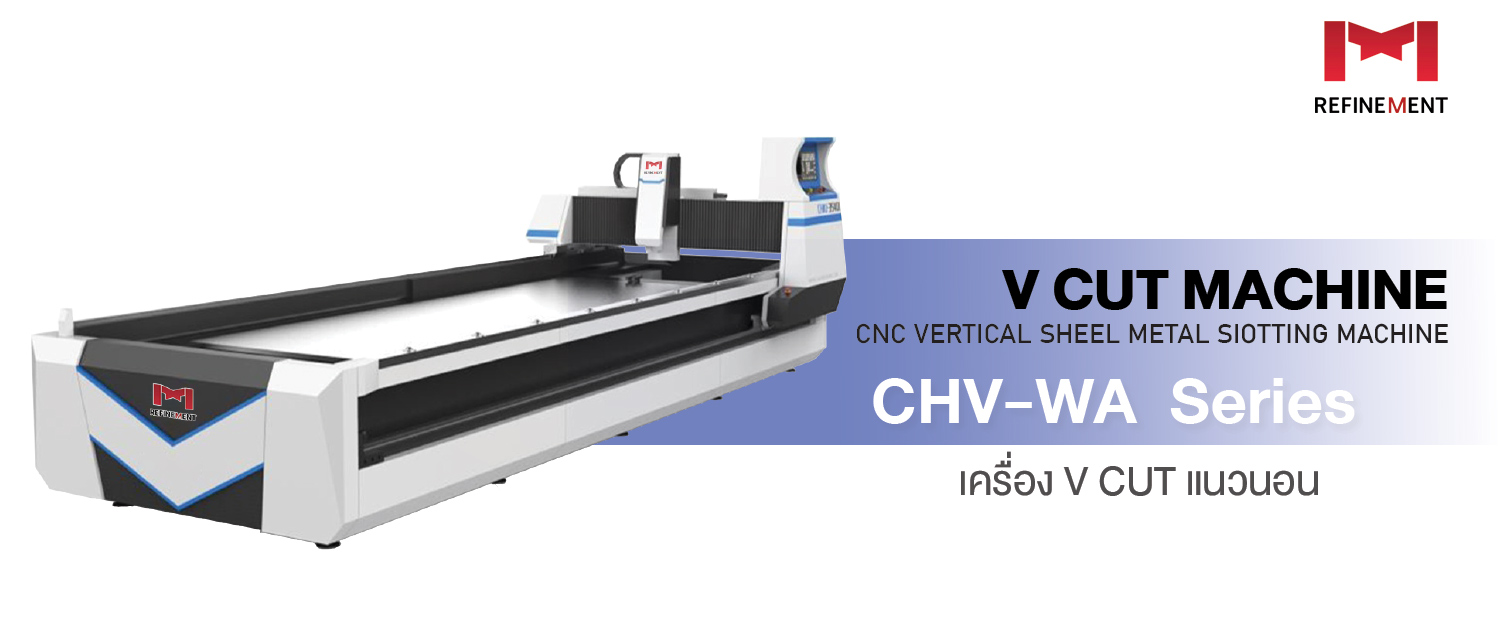

Features - All steel welded structure, high strength, little deformation - NC control, process automatically - Hydraulic clamping and loosen, automatically - Blade tool moving, the work piece is fixed. Cover a small area - Wear mesa can be quickly changed to improve the life of the machine Use five cutters, high efficiency - Removable supporter in front of the working table, processing the long work pieces - Servo motor, accurate positioning, high precision - The operate system is precise unit of electric, pneumatic and hydraulic. Easy operate, flexible motion, high efficiency, low noise, no environment pollution

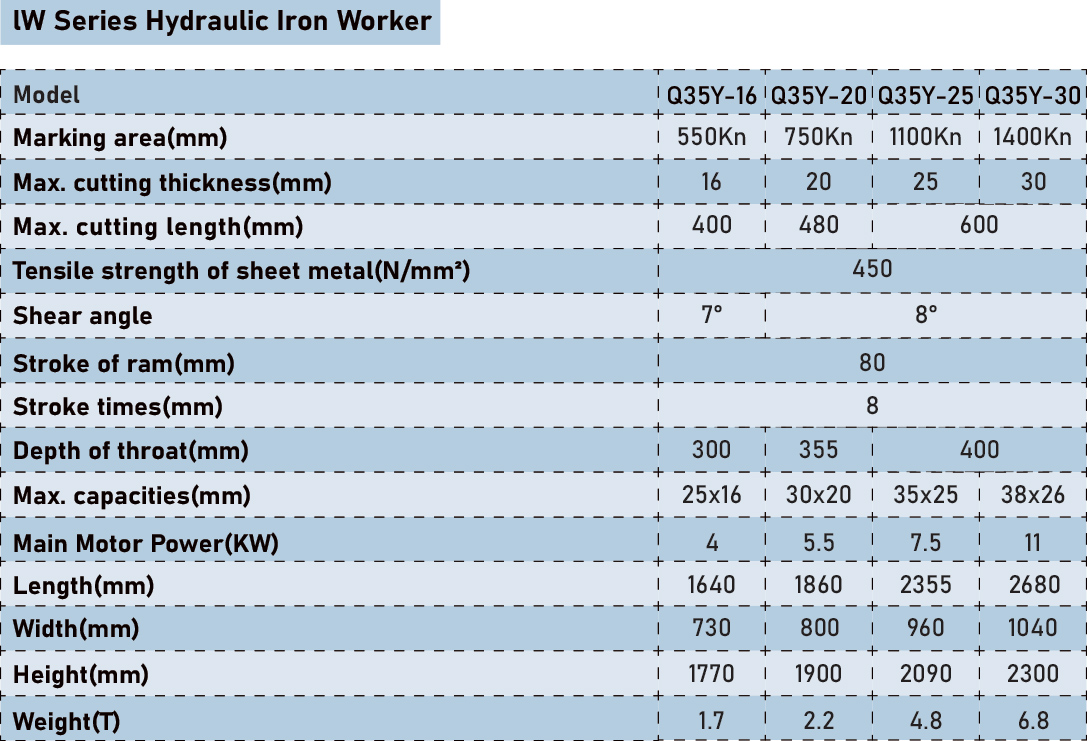

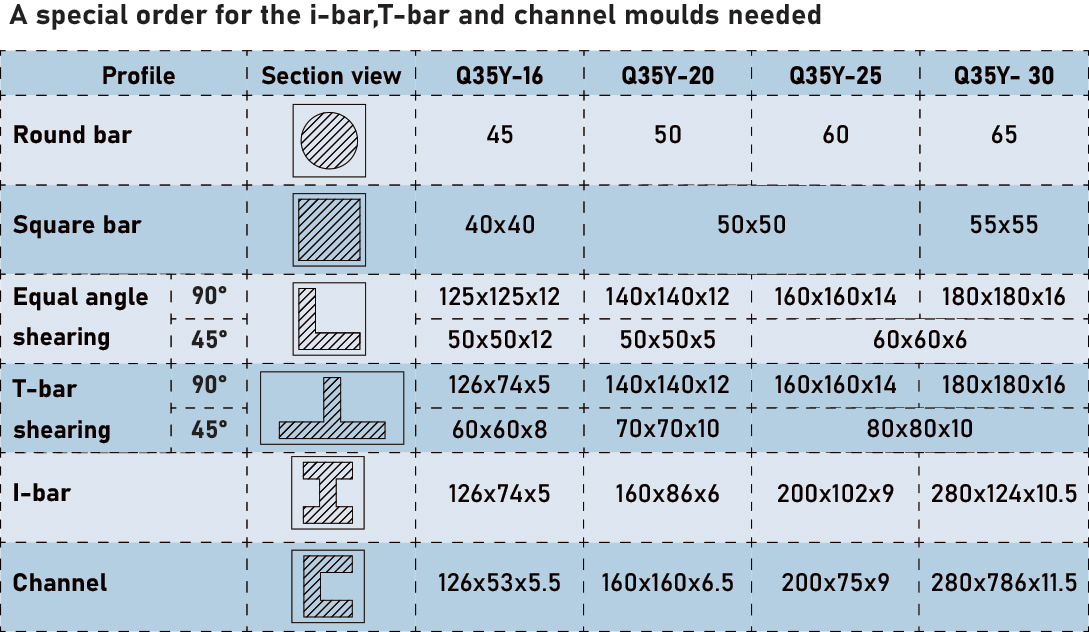

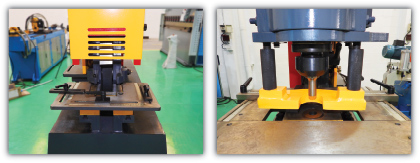

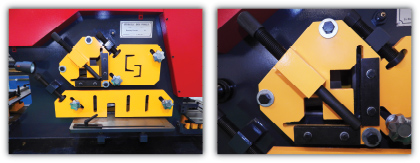

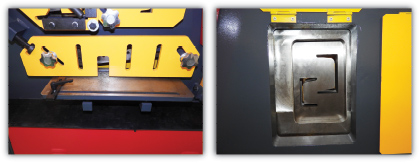

Punching Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change. Shearing Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg.This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.large 15″squaring arm with inlaid scale.Special anti-distorted blade for quality cutting.Lower blade has four usable edges.There is screw allow for gap adjust no shim needed. Notching Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic iron worker is perfect for notching out metal plate, angle iron and much more. The notching station also has an oversized table with material stops. This section of the machine can also be outfitted with the optional vee notcher. Bending Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safty, function, capability and maintenance

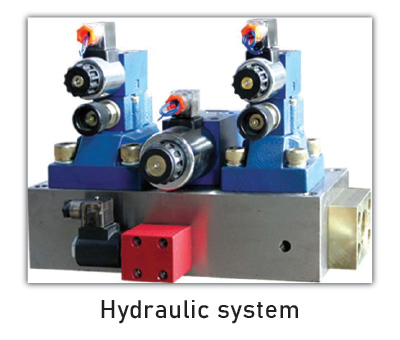

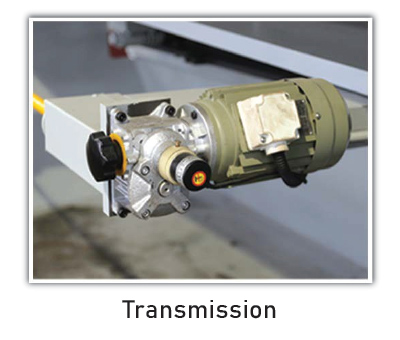

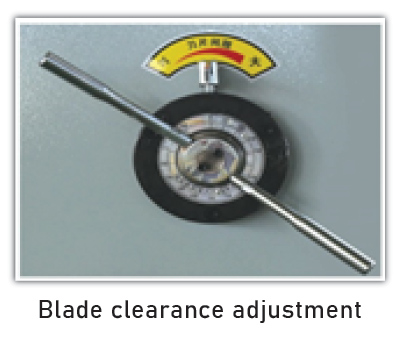

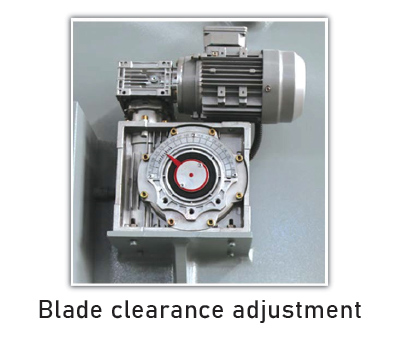

The model of this hydraulic shearing machine / cutting machine is ,steel welded structure with stress-free for reliable performance,hydraulic transmission and accumulator return stroke, characterized by easy operation, reliable performance and fine appearance. Basic features • Steel welded structure with stress-free for reliable performance • Hydraulic transmission and accumulator return stroke,characterized by easy operation,reliable performance and fine appearance • Shadow line lighting • Full or short stroke adjustment of blade holder to achieve high efficiency and productivity • Foot switch for operation with emergency stop • Blades with high tensile strength for cutting carbon steel and stainless steel • Indicator-based adjustment of blades clearance is easy, convenient and swift

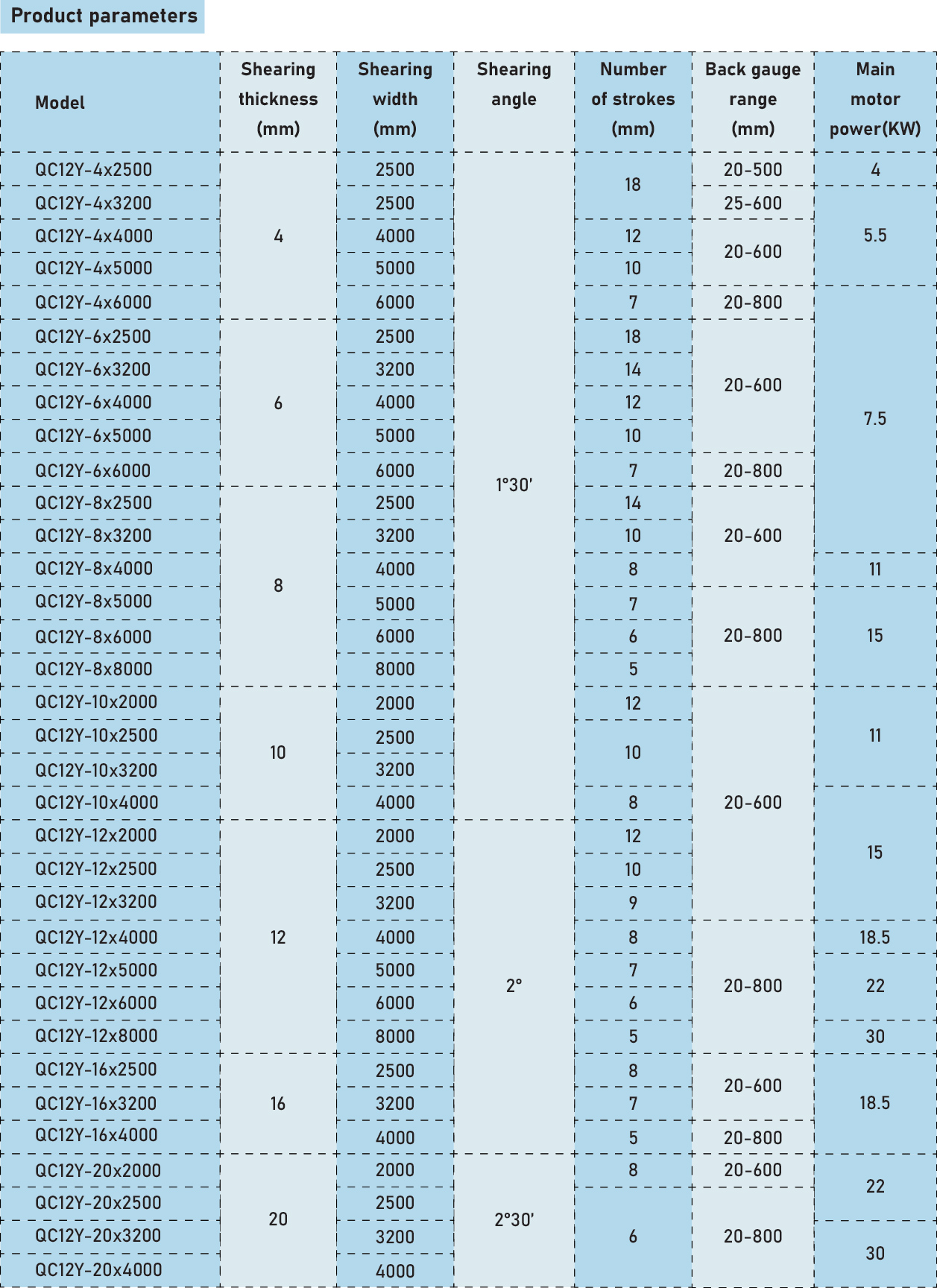

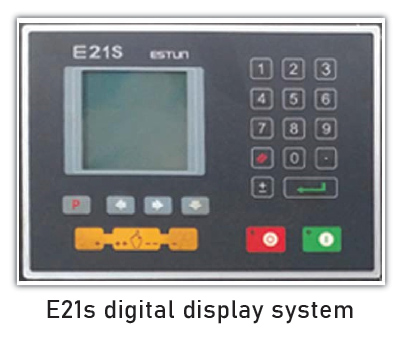

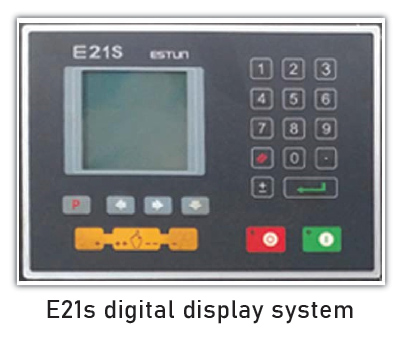

The model of this nc hydraulic guillotine shear is With E21S NC controller,E21 can control the movement of backgauge,achieving efficient and highly precise positioning;Adjustable rake angle to minimize deformation of sheared plate. Basic features • Steel welded structure with stress-free • Three guide trolleys enable accurate movement and fine shearing results

เครื่องอเนกประสงค์ ตัด เจาะ บาก คาร์บอนสตีล สแตนเลส อลูมิเนียม

เครื่องบากมุม คาร์บอนสตีล สแตนเลส อลูมิเนียม

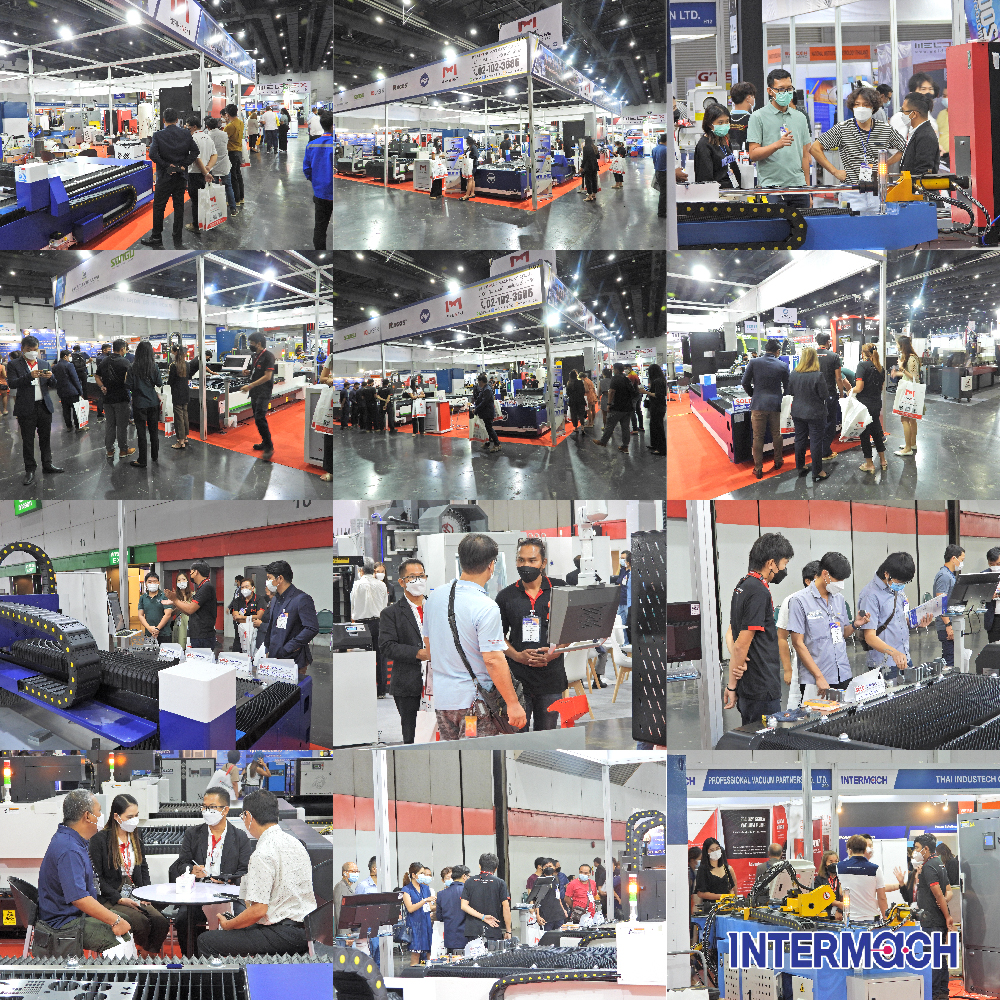

INTERMACH 2023

ประมวลภาพบรรยากาศงาน INTERMACH 2023

ที่จัดขึ้นในวันที่ 10-13 พฤษภาคม 2566 ที่ไบเทคบางนา

บริษัทรีไฟน์เม้นท์ แมชชีนเนอรี่ ขอขอบคุณทุกท่านที่ให้ความสนใจเยี่ยมชมบูธ

และมียอดจองเข้ามาอย่างมากมาย ยกเครื่องมากมาย มาโชว์กันที่งาน 𝑰𝑵𝑻𝑬𝑹𝑴𝑨𝑪𝑯

ใครกำลังตามหาเครื่องจักรสำหรับงานโลหะต้องห้ามพลาด

ลงทุนทั้งที ต้องเลือกสิ่งที่ใช่

เพราะเราไม่ได้จบแค่การขาย

เรามีทีมช่างผู้เชี่ยวชาญพร้อมดูแลคุณ

เรื่องเครื่องจักรและบริการไว้ใจรีไฟน์เม้นท์!

INTERMACH 2022

ประมวลภาพบรรยากาศงาน INTERMACH 2022

ที่จัดขึ้นในวันที่ 18-21 พฤษภาคม 2565 ที่ไบเทคบางนา

บริษัทรีไฟน์เม้นท์ แมชชีนเนอรี่ ขอขอบคุณทุกท่านที่ให้ความสนใจเยี่ยมชมบูธ

และมียอดจองเข้ามาอย่างมากมาย ยกเครื่องมากมาย มาโชว์กันที่งาน 𝑰𝑵𝑻𝑬𝑹𝑴𝑨𝑪𝑯

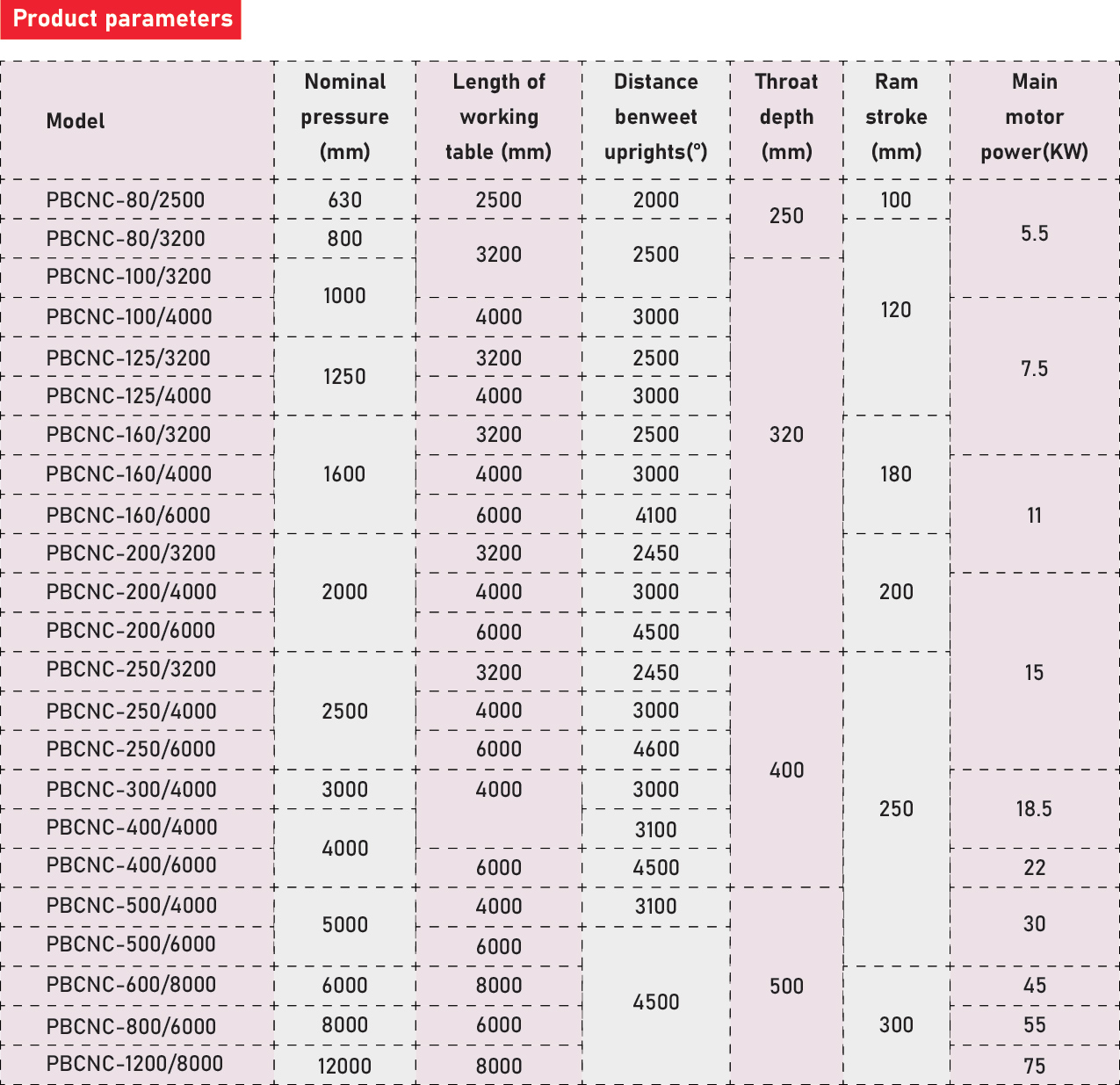

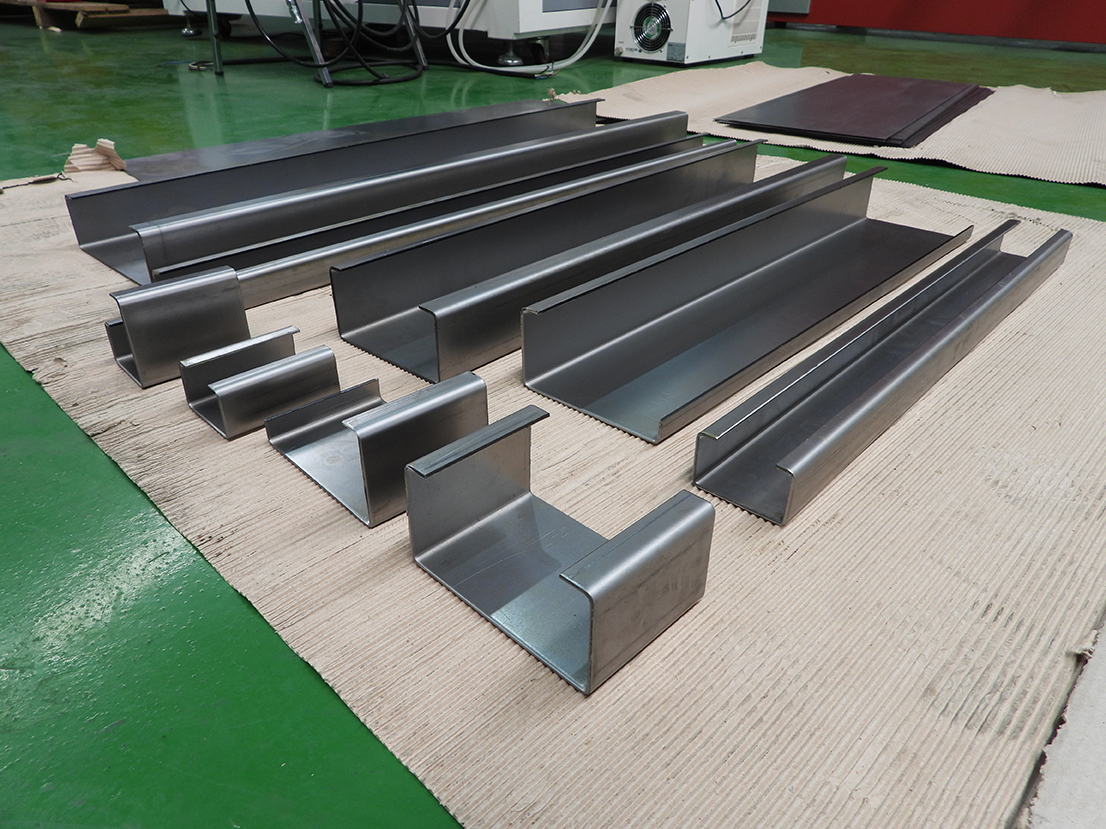

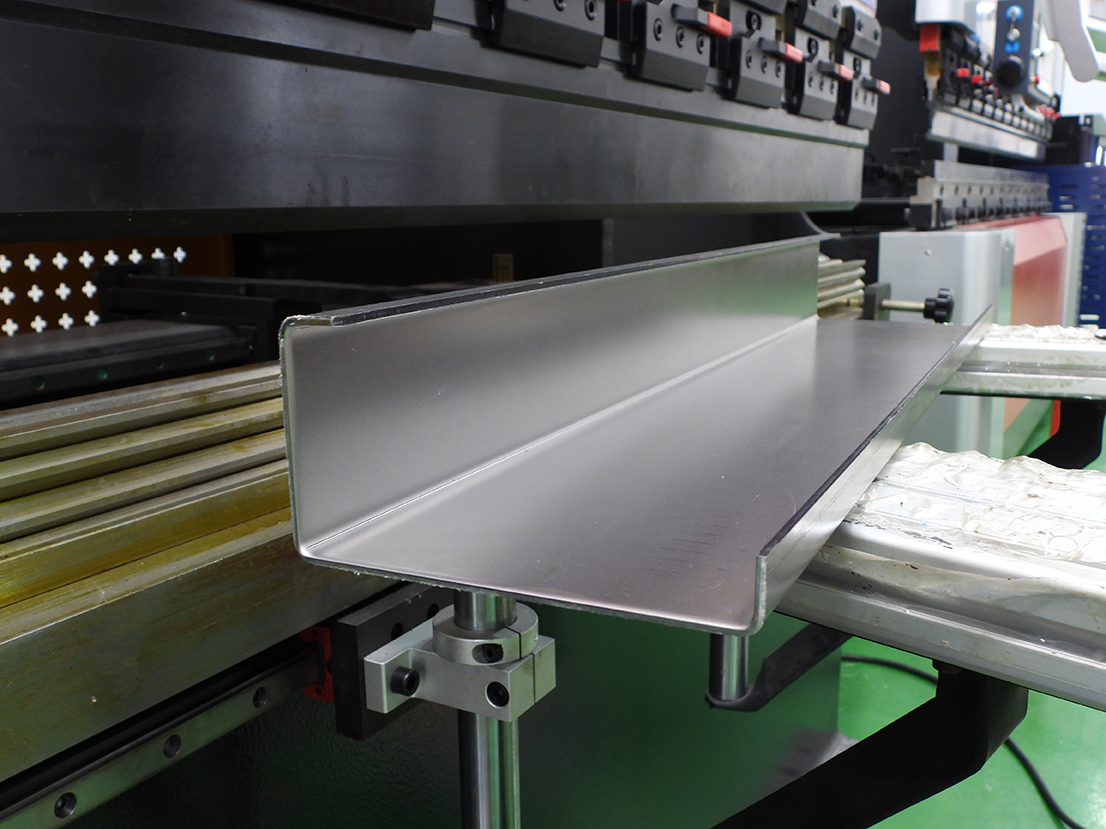

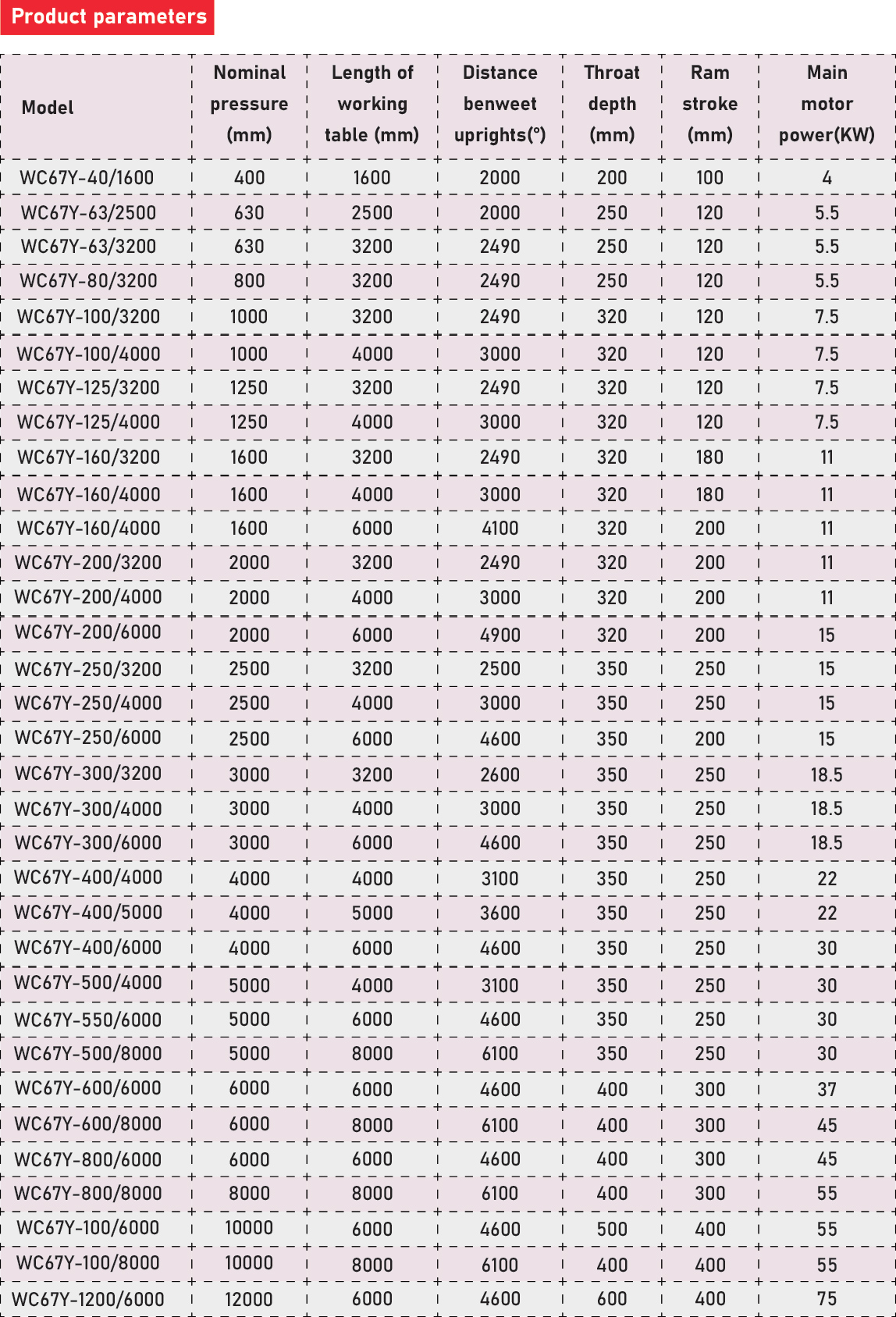

PB series electro-hydraulic servo synchronous CNC bending machine adopts electro-hydraulic servo valve double cylinder synchronous control, hydraulic convex automatic compensation system; The back gauge mechanism can control multiple back gauge shafts; The machine body is welded by steel plate, the whole machine is tempered, the hydraulic system adopts an integrated control system, imported sealing ring, beautiful and simple appearance; The numerical control system adopts DA58W/DA66/DA66W/DA52 numerical control system of Dutch Delem company, Chinese menu graphic display, equipped with upper module speed clamping device. CNC press brake CNC series hydraulic press brake has two hydraulic cylinders with electro hydraulic servo valve. Deflection can be compensated by hydraulic vaulted back-off system. Backgauge mechanism can control several backgauge axes. Its frame is welded with steel plate and is treated with annealing. Hydraulic system adopts integrated control system and imported ring seals. It has a beautiful and simple contour. CNC system uses DA65W/DA66W/DA52 system with Chinese manu made in delem company of Holland. It can also be equipped with mould fixture according to customer's requirement.

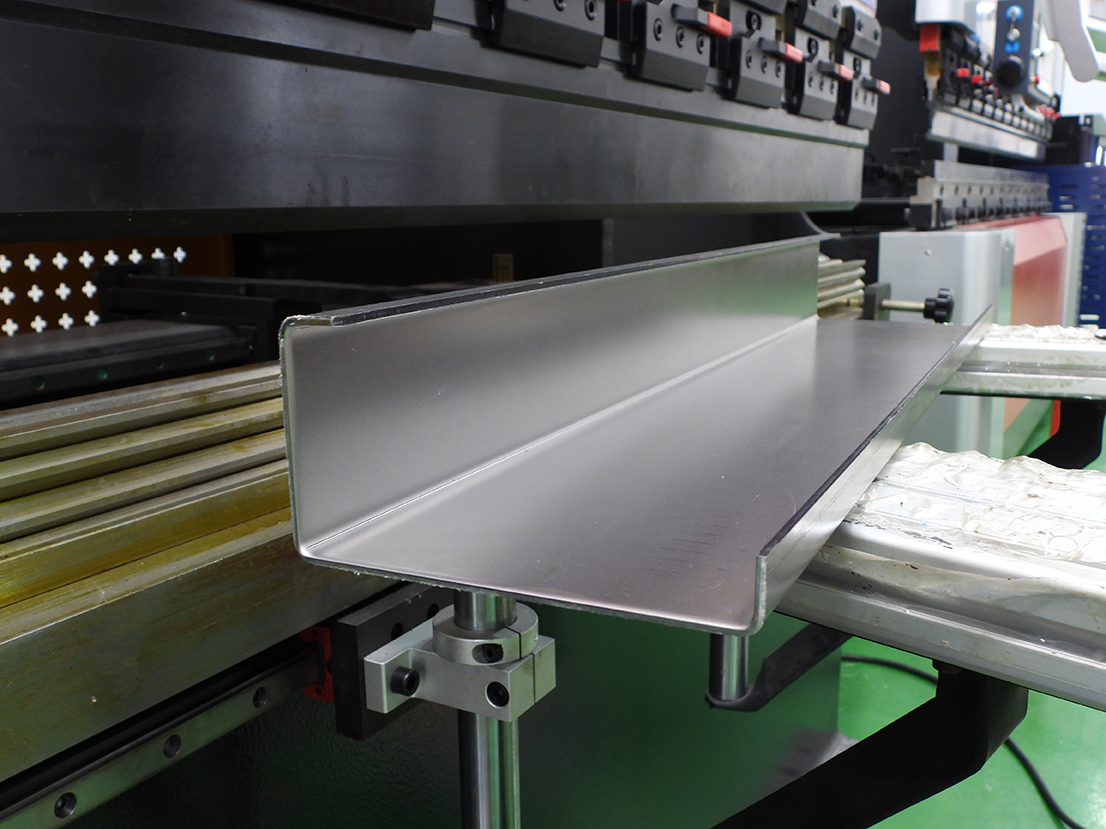

The model of hydraulic plate bending machine as the simple CNC controller,it can control the movement of backgauge,achieving efficient and highly precise positioning;Integrated hydraulic system with hydraulic elements and sealing parts from reputable manufacturers to reduce hydraulic tubes and ensure highly reliable and sage performance. Basic features · Total steel welded structure and stress elimination by vibration. · High mechanical strength and strong rigidity. · Ram stroke hydraulic approaching downward,stable and reliable. · E21 can control the movement of ram stroke and backgauge,achieving efficient and highly precise positioning. · Wedge compensation on top punch clamping. · Simplified top blades clamping with micro-adjustment wedges,for easy operation and high precision. · 2 Sliding front sheet support arms mounted onto T slot of the bed. · Segmented 88° top blade. · Solid one block four face multi V die. · Approved stable and reliable hydraulics. · Stop fingers with milscale for plate bending machine.

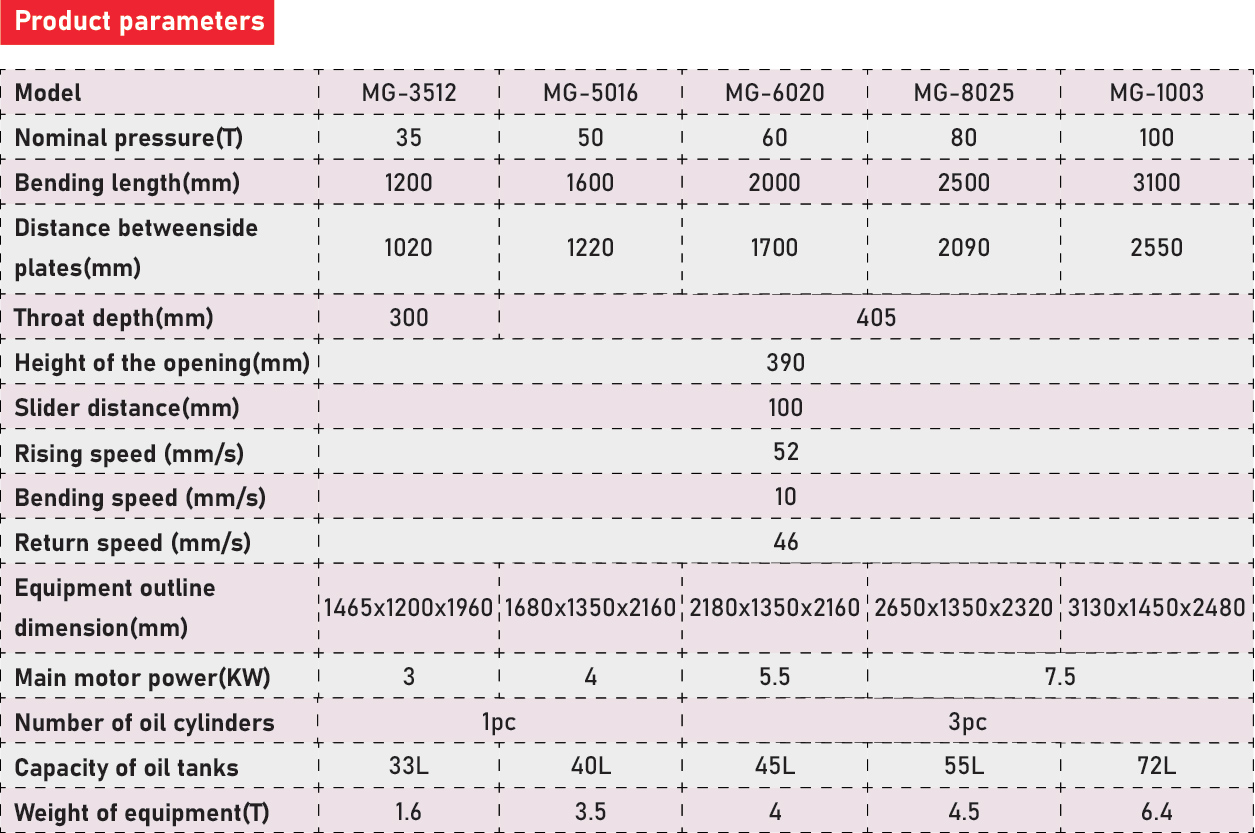

MG series is the best upstroke CNC bending machine in this class; the part output is up to three times higher than a traditional downstroke CNC pressbrake.

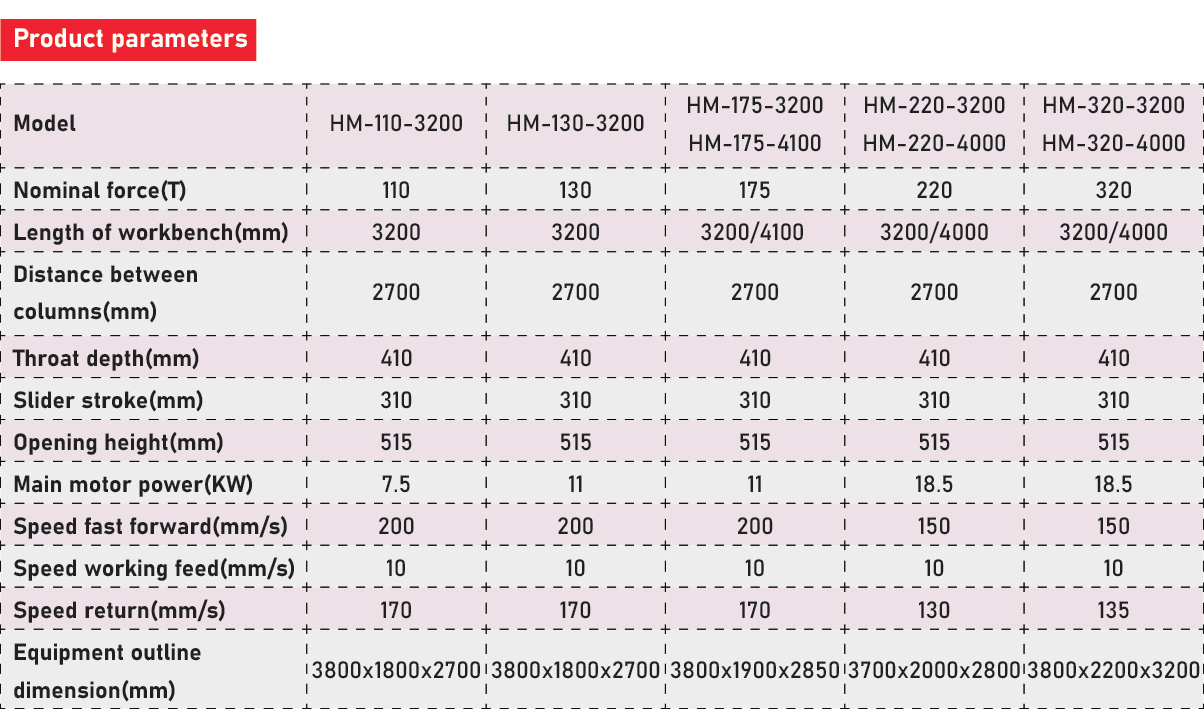

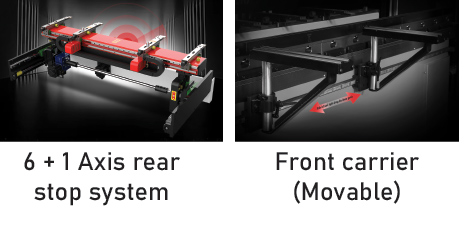

HM series is the best bending machine of industry benchmark, has the most advantage for thick, or long plates. HM series product maximum thickness is 20 mm, and each bend program accuracy are less than 0.05 mm.

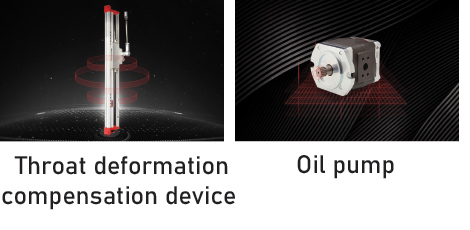

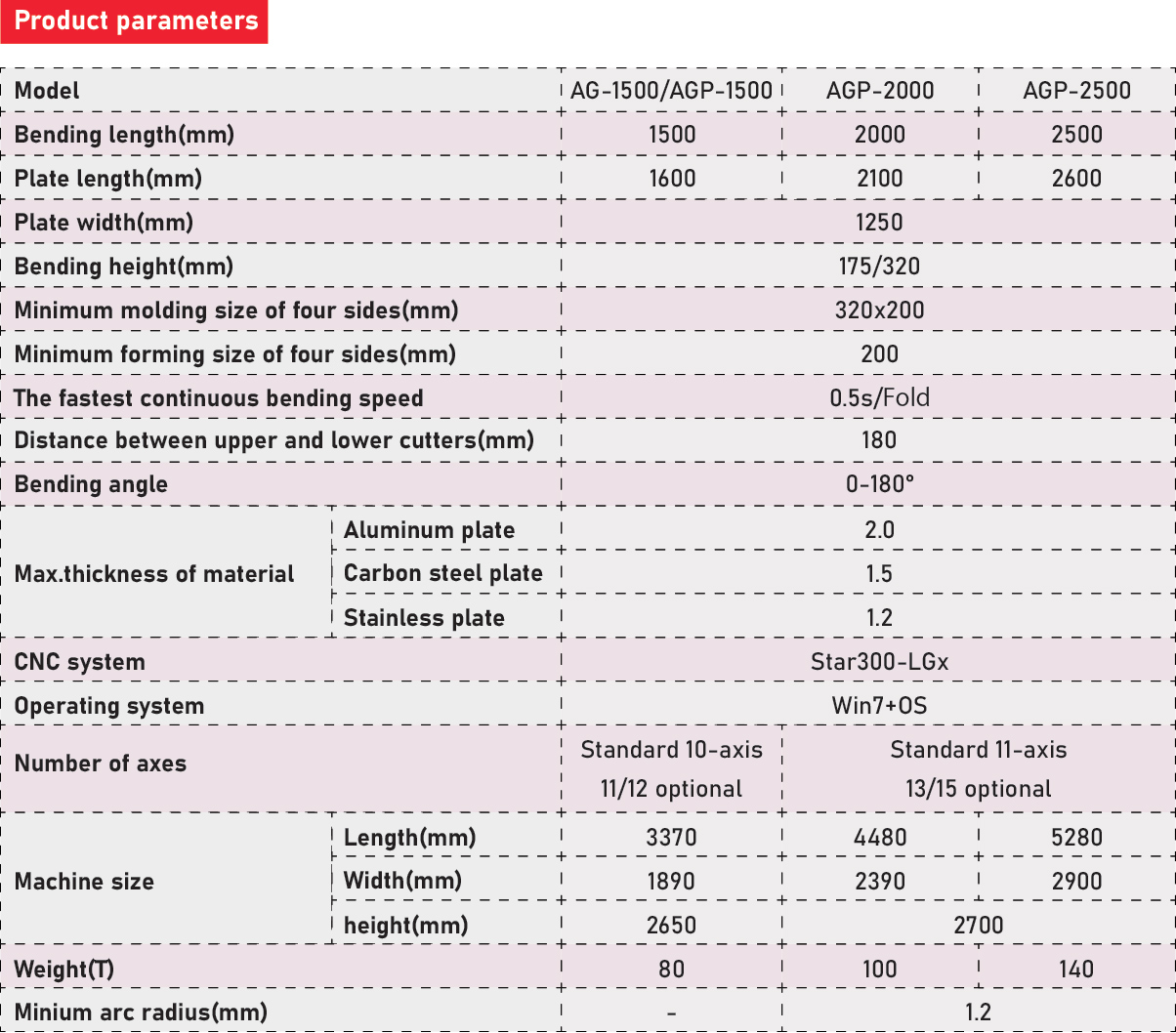

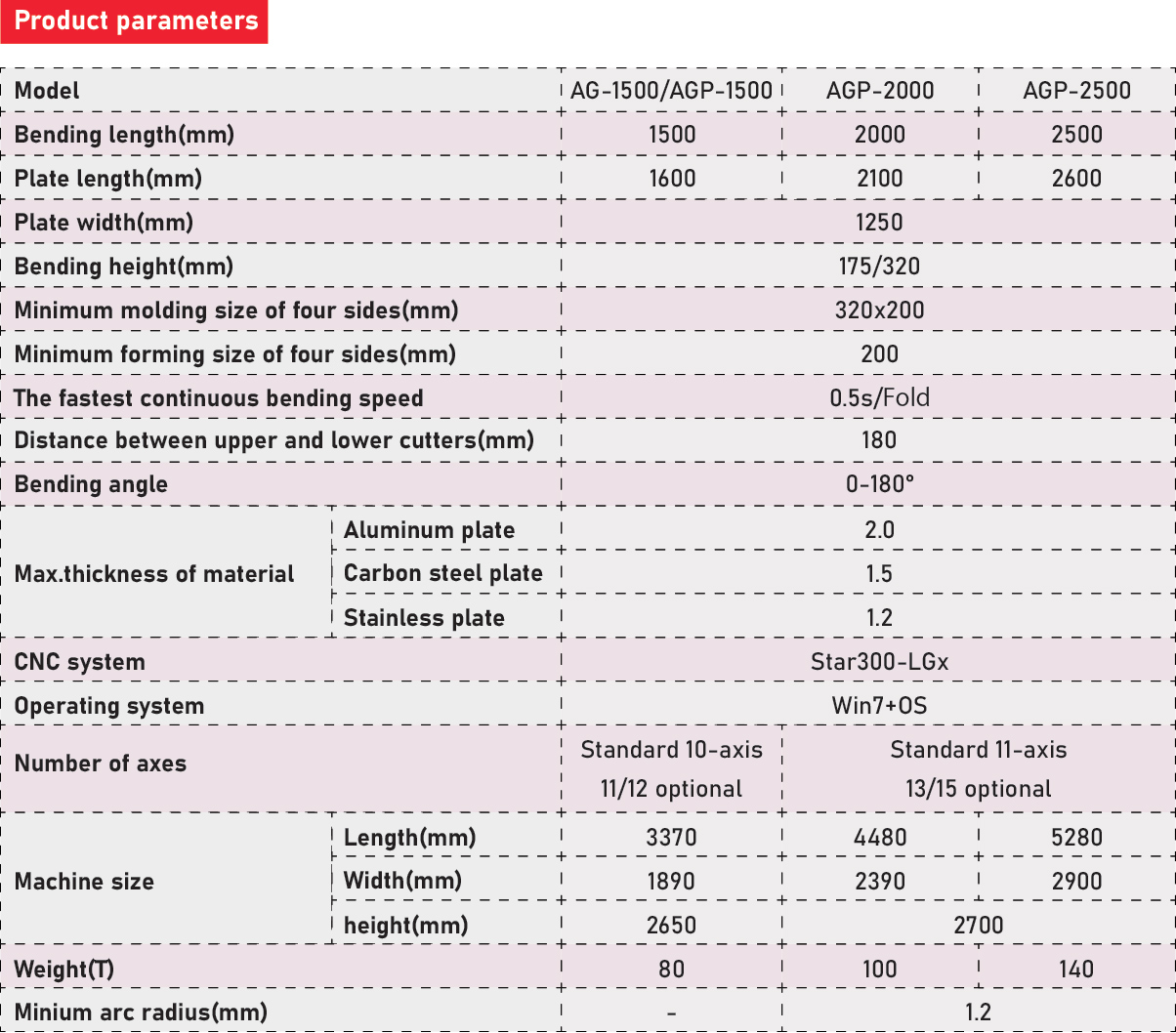

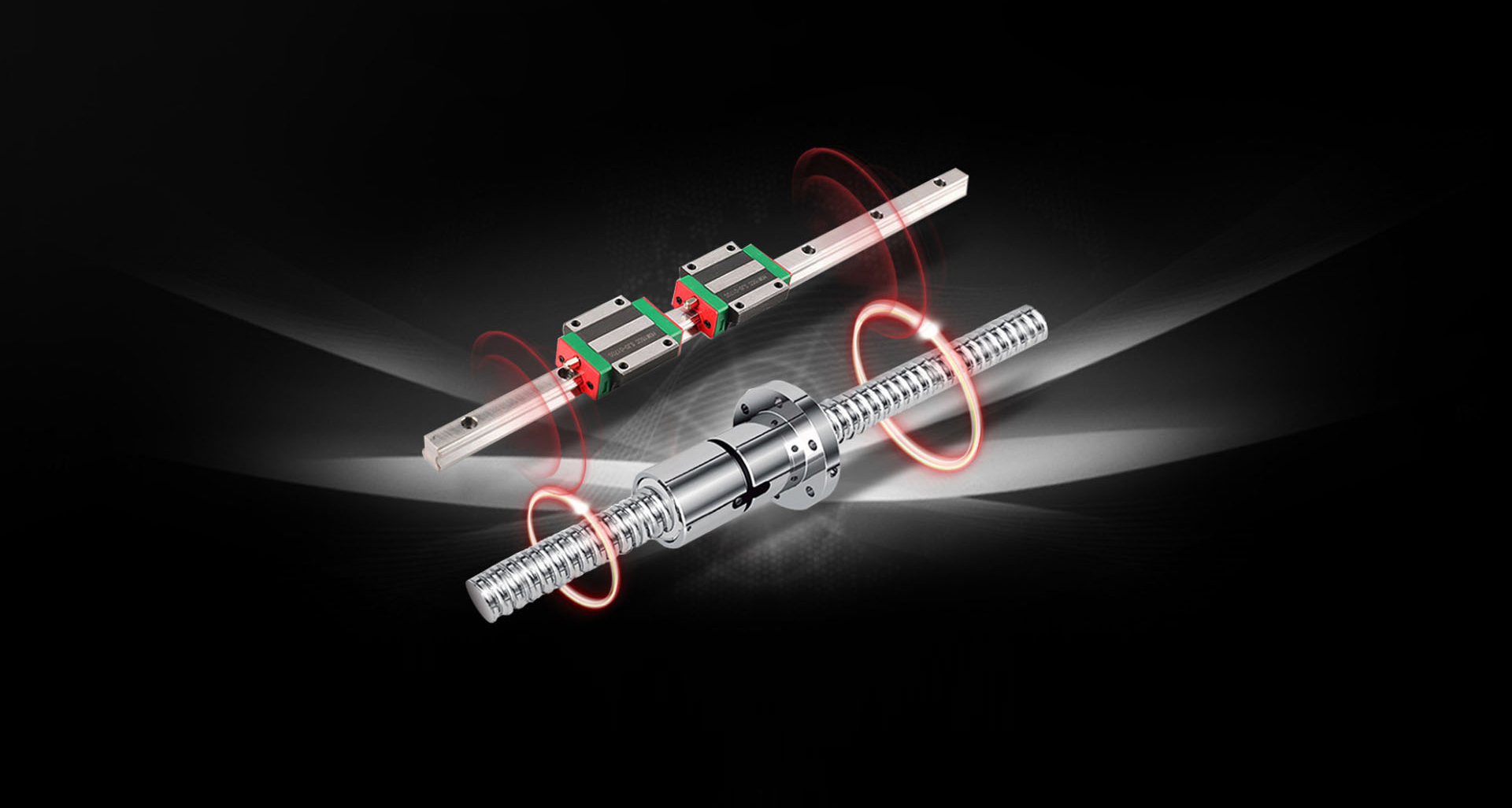

The AG Series is a flexible and intelligent bending machine. The entire equipment is designed and produced in accordance with the standard for high-precision machine tools. High-grade casting parts are used. The casting and welded parts are subjected to the stress release process treatment and the high-precision machine tool is machined as a whole body, to ensure the precision, stability and high rigidity of the machine tool during the long period of operation

The AG Series is a flexible and intelligent bending machine. The entire equipment is designed and produced in accordance with the standard for high-precision machine tools. High-grade casting parts are used. The casting and welded parts are subjected to the stress release process treatment and the high-precision machine tool is machined as a whole body, to ensure the precision, stability and high rigidity of the machine tool during the long period of operation

เครื่องพับโลหะแผ่น คาร์บอนสตีล สแตนเลส อลูมิเนียม

เครื่องพับโลหะแผ่น คาร์บอนสตีล สแตนเลส อลูมิเนียม

• High Rigidity Enhanced Aviation Aluminum Gantry, improve the gantry strength and rigidity and much lighter. • Finite element analysis of gantry help to achieve the best critical state of dynamic performance. • Integrated structure design, reasonable overall layout. • Rack and pinion structure, servo drive, secondary annealing treatment of high rigid welding frame with high accuracy and stability. • SMC (High Pressure Solenoid Valve and precision electronic control proportional valve), Siemens, Schneider Electric components. • Professional laser cutting software with graphic layout and sharp corner smoothing functions, fast piercing & cutting. • Fiber laser has better Industry-leading wall-plug efficiency, less power consumption. • High integration air system: high/low air pressure alarm, N2/O2/High pressure air automatic switching, real-time air pressure monitoring function.

Model |

Fast3015A / Fast4020A / Fast6025A / Fast8025 |

Working area |

3000x1500 mm. / 4000x2000 mm. / 6000x2500 mm. / 8000x2500 mm. |

Overall dimension |

9000x2450x2260 mm. / 11000x3650x2200 mm. / 15500x4350x2200 mm. / 19800x4350x2200 mm. |

Laser power |

1500-20000W |

Weight |

8800 kg / 11500 kg / 13500 kg / 18500 |

Maximum Speed |

100 m/min |

Positioning accuracy |

±0.03/1000 mm/m |

Repeated Positioning accuracy |

±0.02/1000 mm/m |

Software |

Cypcut |